Leicester City FC, trophies

… and Gary Lineker’s underwear!

What have Gary Lineker’s underwear, 15 trophies, and a sheet metal fabricator in Loughborough got in common?

2016 has seen some unprecedented activity regarding Leicester City Football Club: The Club itself won the Premier League beating odds of 5000-1 at the beginning of the season; Platinum Steelworks was asked to fabricate 15 3ft high replica trophies; and Gary Lineker presented Match of the Day in his underwear. As Lineker’s underwear has been covered enough (or maybe not…) in this past year, you’ll be thankful to know this article is going to talk about the trophies!

When Leicester City FC won the Premier League earlier this year almost 240,000 fans took to the streets of Leicester City, to celebrate the win. Fans were joyous because this wasn’t just the first time in history that the Club had won the League, but also the first time in a decade that the Club had even played in this League.

Around about this time, some fans based in Loughborough, who were so impressed with the win, decided to commission a local steel fabricator to make replica trophies of the Premier League Cup. Standard sized trophies would not be good enough however: The fans wanted 3ft high and 2ft wide Cups, and 15 of them! Platinum Steelworks was chosen for the work.

Platinum Steelworks is a Sheet Metal Contractor based in Loughborough. Run by Gurnam Singh the company usually fabricates barriers and gates, staircases and balustrades, and structural metal fabrications for buildings. The trophies were an unusual request, but Platinum Steelworks was up for the challenge.

As the trophies were made from steel, and steel needs to be protected from the environment with a galvanized coating, Premier Galvanizing Hull (a division of Joseph Ash Galvanizing) was also hired by Platinum Steelworks, and pulled onto the project.

Premier Galvanizing Hull have supplied Platinum Steelworks with galvanizing services for over 14 years.

A number of trophies have so far been fabricated and hot dip galvanized by Platinum Steelworks and Premier Galvanizing. And some Leicester City fans who have received them, have placed them in their gardens for passers-by to see.

Here are some photos of the trophies, as well as the galvanizing team at Premier Galvanizing.

Next page

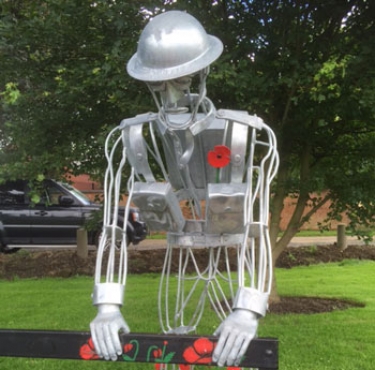

Tin Tommy sculpture, looking reflective at 2016 Remembrance Day Parade

On Sunday 13 November, the town of Immingham in North East Lincolnshire, held a Remembrance Day Parade at the Pelham Road War Memorial. The event was a fitting tribute to all soldiers who have lost their lives defending our country.

As part of the ceremony, a new statue stood at the War Memorial, leaning on a memorial seat covered in poppies. The statue was nicknamed Tin Tommy by local school children in the community, and he has become so popular that he even has his own Facebook page.

Tin Tommy was commissioned by the Barton Living Memorial Trust, who raised funds from the local council and communities. The aim of the Trust is “to educate the next generation about the World Wars and the sacrifices that so many made, and to keep the memory alive“.

When standing straight, Tin Tommy is a full-sized six foot high statue of a WW1 era British soldier, with red poppies painted onto parts of his frame. The bench that he leans upon has been designed to allow people to sit and “reflect on life, history and memory“.

Tin Tommy was fabricated by Hodson & Kauss, and hot dip galvanized by one of Joseph Ash Galvanizing’s divisions: Premier Galvanizing Hull.

Hodson & Kauss are expert fabricators who mainly fabricate bridges, walkways, fencing, staircases, and balustrades. Sometimes they are asked to fabricate unusal items such as Tin Tommy too. Hodson & Kauss have been using Premier Galvanizing Hull for all their galvanizing needs, for a long time. Premier Galvanizing are proud to have played a part in the construction of such an important statue.

(More photos of Tin Tommy can be found on the Joseph Ash Galvanizing Flickr site.)

Next pageThe bread and butter of Joseph Ash Galvanizing’s work is centred around galvanizing steel used in transport, farming, construction and infrastructure. We do this for fabricators, fencing and agricultural manufacturers, and large structural steelwork companies. Every so often however we also receive a project from a steel sculptor. The works are unusual, intricate and detailed and we deem it an absolute pleasure to become a part of the sculptor’s artistic process.

The most recent pieces of art that came onto our yard at Joseph Ash Bridgend were two huge steel dragons, fabricated from Phoenix Forge Ltd, a bespoke metalwork and blacksmith’s business based in Carmarthen, South Wales.

Phoenix Forge generally specialises in traditional and contemporary metalwork, producing a wide range of hand forged artistic, decorative and functional ironwork including: gates, railings, balconies, public artwork, curtain poles, fireplace tools, restoration and bespoke commissions. They have also sculpted a number of dragons too!

Two such dragon installations were recently sent to Joseph Ash Bridgend: a dragon curled around a lamp post; and a sleeping dragon.

Will Holland from Phoenix Forge said:

“The dragon lamp post sculpture was vast with a wing span of approximately 6-7 feet and a nose to tail of about 9 feet, however the sleeping dragon was a lot larger, but curled up on a rock with a diameter of 6 feet.”

After spending over 300 man hours, over a period of six weeks, to make each dragon, Phoenix Forge asked Joseph Ash Bridgend to hot dip galvanize both sculptures. Galvanizing is an important finish for outside sculptures such as these as the treatment protects the steel from atmospheric conditions and rust.

It is important for blacksmiths such as Phoenix Forge to be able to trust suppliers, especially with one-off pieces of art. Holland said the following about Joseph Ash:

“We send all of our hot dip galvanizing work to Joseph Ash Galvanizing. We’ve been using them for a couple of years and they do an excellent job for us. They are incredibly helpful, reliable and take good care of our work – which is so important given the amount of man hours it takes us to fabricate a sculpture.”

The dragon climbing the lamp post sculpture was commissioned by a private collector in Shropshire who has bought several similar sculptures from Phoenix Forge over the last few years. The artwork has now been installed outside the client’s private residence.

In contrast the sleeping dragon – which is made up of over 5000 individual steel scales – was fabricated as a show piece for Phoenix Forge’s display at the 2016 Royal Welsh Show at the National Botanic Gardens in Wales. The sculpture is currently on loan at the Gardens until a permanent home is found.

To see a video which shows how Phoenix Forge make dragons, watch YouTube here.

We’re looking forward to receiving more projects from Phoenix Forge in the future!

Next page

Steel fabricated by Caunton Engineering and hot dip galvanized by Joseph Ash Galvanizing used in new Norfolk biomass plant.

In 2017 a new energy plant will open in Norfolk, with an electrical capacity of 44.2MW and the ability to supply 82,000 homes with energy.

For environmentalists and engineers alike, it is an interesting project as the energy will be generated from burning organic matter. Local farmers are interested too as they will be supplying (and making an income from) the 250,000 tonnes of straw and woodchip that will be used to generate the energy.

The project is being funded by two Scandinavian organisations – Burmeister & Wain Scandinavian Contractor (BWSC) and PensionDanmark. The architect and structural engineers are Ramboll, and the steelwork contractor is Caunton Engineering Ltd. Joseph Ash Galvanizing also has an interest in the project as we were entrusted by Caunton Engineering to hot dip galvanize the steel which they fabricated.

This steel, which was fabricated by Caunton Engineering, included:

- Stairs

- Platforms

- Two barns for straw

- The roof of the woodchip barn

- Crane beams

- Boiler house

- Turbine hall.

It has been a huge project involving about 1500 tonnes of steel. In fact, the steel beams for the turbine hall alone were 33m long and 8 tonnes in weight each.

Gary Hatton of Caunton Engineering said that they chose Joseph Ash Galvanizing because of their ability to turnaround the high tonnages of a complex galvanized frame to programme in accordance with the required Quality Assurance.

Steven Hopkins, Managing Director at Joseph Ash Galvanizing said:

“This is exactly the sort of project that we like to be involved in, offering an opportunity for careful planning well in advance to ensure that the steel components are designed and fabricated to take into account the galvanizing process. This promotes the best possible quality of finish with minimum waste and less of an environmental impact. Demanding jobs like this bring out the best in us, in order to achieve total customer and end-user satisfaction. The experience gained then benefits our entire customer base.”

Environmental concerns play a large part in our own factory processes at Joseph Ash Galvanizing so it is pleasing to have been part of a project which uses biomass as a new source of fuel. The new energy plant has also supported over 250 jobs during the construction phase, and will create 36 new positions once it is completed and operational.

For further information about the new biomass plant, visit New Steel Construction or the Eastern Daily Press.

Next pageWith Summer about to kick-in (hopefully!) children up and down the country will be making use of local playground facilities – laughing, giggling and generally having fun. Whilst ‘fun’ is definitely the main aim of children’s playgrounds, parents and playground owners also want to know that children are safe. With this in mind, Newark and Sherwood Homes Limited, recently installed a new Mono Hinge Gate at the Forge Close Play Area in Nottinghamshire.

The new gate was needed at the playground because the old timber gate began to require more and more adjustments from the play park repairs contractor, to ensure it closed correctly, and was also easy enough for people with disablities to operate.

Lee Powell, Architectural Technician, Newark and Sherwood Homes Limited, chose Joseph Ash Medway to provide a new gate after a recommendation from a tutor who provides RoSPA Play Park Inspection training. Lee said: “I also chose Joseph Ash Medway because it is important for the gate to open and close easily to allow people with disabilities to access the playground.”

Mono Hinge Gates (by Joseph Ash Medway) are one of the safest gates available for the enclosure of children’s playgrounds:

- With a hydraulic mechanism tested to 100,000 cycles, the gate is fully compliant with the European Standards for Playground Equipment BS EN-1176.

- The gate opens to 110 degrees, which means that recoil is prevented and finger traps and crush points become a thing of the past.

- The gate incorporates varying closing speeds, making it virtually impossible to beat when it comes to safety.

- The gate is also wheelchair accessible and complies with DDA regulations, making it the ideal choice for long-term refurbishment and renovation schemes.

- The gates are vandal resistant.

Mono Hinge Gates are easy to install, and are designed to open to the left or right. They can be single or double, to match the needs of any environment, and they are assembled and supplied as complete units, enabling fast and easy installation to the correct specifications without costly site works.

The gates are also fully hot dip galvanized by Joseph Ash Medway to protect from corrosion for up to 60 years, and can also be powder coated with a choice of colours to meet any specification.

Newark and Sherwood Homes Limited chose a single gate in a deep green colour.

For more information about the Mono Hinge Gates please contact Mandy Filkins at Joseph Ash Medway on 01795 419816 or visit the website.

Next pageKew Gardens in South West London has an international reputation as the centre for botanical research, as well as having an unequalled reference collection about all types of flora and fauna. With over 300 acres of land, beauty is as far as the eye can see, and none more so than from the Treetop Walkway, hot dip galvanized by Joseph Ash Galvanizing in 2008.

The Treetop Walkway at Kew Gardens was a new attraction which opened on International Biodiversity Day in 2008. At 18 metres high and over 200 meters long, visitors to the park can walk amongst the treetops of sweet chesnut, lime and oak trees. The Walkway is accessible via a lift or 118 steps and not only provides great vistas across the park and through the trees, but allows people to experience nature amongst the tree tops.

As Joseph Ash Galvanizing was given the responsibility in 2008 for protecting the walkways on the steel structure with a galvanized finish, we decided to take advantage of the Summer weather a few weeks ago in order to revisit the structure.

Take a look!

The Treetop Walkway was designed by Marks Barfield Architects, who contracted Britland (based in Dover) to manufacture and install the metalwork for the structure. Britland then engaged Joseph Ash Galvanizing as a specialist sub-contractor to treat the steel with a hot dip galvanized finish that blends well with the environment and will be maintenance-free for 60 years.

In 2008, Bob Ockendon from Britland commented: “The structure itself is unusual in the fact it is formed from ‘weathering steel’ which is only available in sheet form which then had to be fabricated to make the various members. It is intended to weather to blend in with the environment, but Joseph Ash Galvanizing treated and coated all the grilles and side panels to protect them while matching the surroundings. We decided to go to Joseph Ash Galvanizing because of the service the company offers and the standard of work they have done for us in the past.”

Eight years later, we are happy to report that the Treetop Walkway is proving a popular attraction with many people enjoying the views and traversing the platforms amongst the trees. The structure looks just as amazing today as it did in 2008, and the steel has weathered well and looks stunning set into the nature of the Gardens.

No doubt we’ll head back for another visit to Kew Gardens and the Treetop Walkway at some point in the future. If you’re looking for a great out out this Summer, we recommend you visit the attraction too.

Next page

On 10 November 2017 France will host a service of remembrance to commemorate the centenary of the end of the Battle of Passchendaele during World War One. The event has been named The Passchendaele Salute 2017.

During the service the guns will fire 100 rounds to recognise 100 years since the battle ended. At least 10 Great War guns will be used, which will be manned by teams from Australia, New Zealand, Canada, the UK, Belgium and France.

The Battle of Passchendaele was fought by the Allies against the Germans, on the Western Front from July until November 1917. Field Marshal Haig’s main aim for the battle was to destroy German submarine pens by breaking through to the coast of Belgium. Often referred to as the ‘Battle of Mud’ because the dreadful weather hampered progress, it was a costly campaign as Haig only managed to gain a few miles, and yet 325,000 Allied troops died, as well as 260,000 Germans.

As hundreds of thousands of lives were lost during the Battle, it’s important to remember the men who served. With this in mind Joseph Ash Galvanizing is happy to support the event by donating 3-4 Joseph Ash Galvanizing lorries, for a period of 2-3 days, to help John Slough of London (a client of Joseph Ash Galvanizing who refurbishes antique guns) carry some of the guns from the UK to Lille in France, where the Salute will take place.

The Passchendaele Salute 2017 will not only commemorate the men who died during the Battle, but it will also raise money for a good cause, as Combat Stress is the beneficiary charity.

You can follow news about The Passchendaele Salute 2017 here. Keep an eye on the Joseph Ash Galvanizing website too as we’ll be charting the journey of our lorries, as well as the event in our news stories nearer the time.

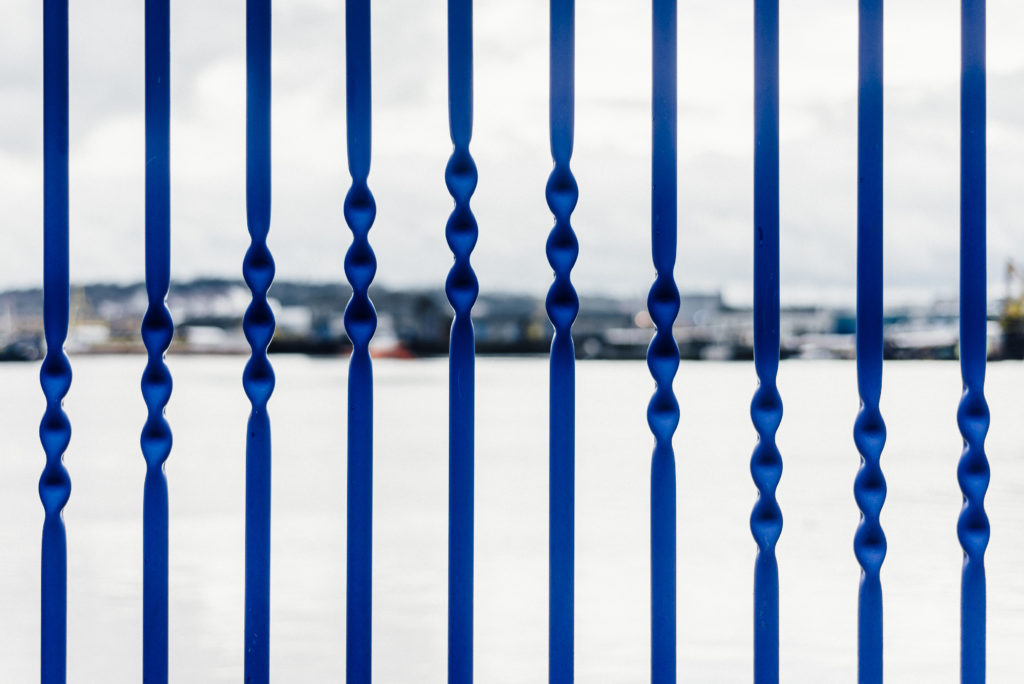

Next pageAs part of the first phase in a £1 billion regeneration scheme of the Medway Towns in Kent, more than 300 metres of bespoke railings were installed along Strood Waterfront. Galvanized and powder coated by steel finishing specialist Joseph Ash Medway, the metal railings are still looking and performing as good as new some 15 years after the installation.

Appointed by main contractor W.S. Atkins on behalf of Medway Council, bespoke architectural metalwork specialists Claydon Architectural Metalwork (CAM) designed and installed a new railing system that would run alongside the redeveloped riverfront and around a play area in Watermill Gardens. Using the company’s patented tube crushing techniques, CAM produced attractive and secure decorative railings that would provide excellent edge protection.

”We designed and installed over 300 metres of railings on Strood Waterfront, all of which needed to be galvanized and powder coated. For this, we turned to the unrivalled quality and service of Joseph Ash Medway,” said Phil Pizey, Owner of Claydon Architectural Metalwork. ”Fifteen years later and the railings continue to look as good as new which shows why we use Joseph Ash Medway every time.”

Joseph Ash Medway applied its hot dip galvanizing techniques, followed by a matt blue powder coating finish to the new metalwork. Hot dip galvanizing provides a tough, long lasting finish which, when combined with powder coating, offers an aesthetic, colourful and durable coating that will last for many years.

Operating to stringent quality control processes and fully accredited to all the latest BS and ISO standards, the galvanizing process provides at least 25 years worth of corrosion protection often considerably more.

As the redevelopment of Medway Towns has taken shape in the last 15 years, the regeneration of Strood Waterfront and its extensive riverside railing system will continue to look its best thanks to Joseph Ash Medway.

Next page

Joseph Ash Galvanizing hot dip galvanizes and powder coats steel railings for Claydon Architectural Metalwork and the BSI.

Producing any of kind of project for the British Standards Institute could be a daunting task, because of the very nature of their work. As one of the world’s largest independent certification bodies for management systems, with over 120,000 registered sites across the globe, the BSI has very high standards to meet! Despite this, Claydon Architectural Metalwork (CAM) was asked to create and install new railings outside the BSI’s building in Hemel Hempstead, as part of a larger refurbishment project on the whole building, and Joseph Ash Galvanizing was asked to provide the necessary steel finishing treatments.

CAM was approached by Kirsop, the project surveyors, to design the new front elevation railings for the BSI building. CAM was happy to take on the project and they chose Joseph Ash Galvanizing to provide the finishing treatments – a choice they have been making for the last 20 years, knowing the very high standards of quality and customer care that Joseph Ash Galvanizing provides.

The railings are made from steel and measure 82 linear metres in length and stand approximately 900mm high on top of the existing wall at the front entrance to the building. The total weight of the steel used was just under two tonnes.

As part of the design, CAM managed to incorporate the well known Kitemark and BSI logos into the railing panels with great effect.

Kirsop asked CAM to design and build the new railings in early 2014. By June the railings were fabricated, at which point they were collected by trucks from Joseph Ash Medway (Joseph Ash Galvanizing’s Kent-based plant), driven to Sittingbourne (where the plant is based) and prepared for treatment.

The railings have to last a long time. They need to remain looking good and be protected from corrosion from the elements. With this in mind Joseph Ash Medway treated the steel with a duplex coating of a hot dip galvanized substrate, as well as a powder coated finish.

Duplex Coating = Galvanizing + Powder Coating

Galvanizing: Hot dip galvanizing has been used worldwide for well over a century because it provides a long-life, low-maintenance corrosion protection, which safeguards steel from atmospheric attack.

Powder Coating: This can be combined with a powder coated finish which provides a low maintenance, long lasting, colourful covering for architectural metalwork, fencing, gates and any other steel fabrication. It is a covering which can be offered in a wide variety of durable, colourful, metallic and textured powder coating finishes that are both attractive and guaranteed for up to 25 years.

Once the steel had been treated, Joseph Ash Medway delivered it back to Claydon’s site in Suffolk.

Both CAM and Joseph Ash Galvanizing are very pleased with the railings for the BSI, and work well together as a team.

Claire Rycraft, from CAM said: “As a company it is important for us to adhere to all the required BSI standards when completing work for customers – not just the British Standards Institute! Because of this, we choose suppliers to help us complete projects that also adhere to important standards. Joseph Ash Galvanizing is one such company and we have a great deal of confidence in their work.”

Matthew Hodges at Joseph Ash Medway said: “Aside from the aesthetic appeal of powder coated surfaces, there’s no point investing in a colourful coating unless you know it will last. With Joseph Ash Medway customers can be assured that we are not only approved as paint applicators by AzkoNobel, IGP and Dupont, but we also adhere to the following standards when it comes to galvanizing and powder coating: BS EN ISO 1461 (galvanizing) and BS EN 13438 (powder coating).”

The railings have been standing outside the BSI building for 18 months now and they look great. Because of the high standards of Claydon Architectural Metalwork and Joseph Ash Galvanizing, the gates should be protected and will look attractive to meet the BSI’s exacting standards for many years to come.

About Claydon Architectural Metalwork

Claydon Architectural Metalwork is a family run business, established 30 years ago. Their award-winning designs visually enhance landscapes and urban environments.

They work closely with clients to ensure the facilitation of their creative ambitions, by offering a complete design, manufacture and installation service which guarantees the consistency of CAM’s work at every stage of a project.

Claydon’s passion for design has set them apart for nearly 30 years and has led to an illustrious history featuring work with prominent artists, architects and contractors.

Next pageRhino enclosures: there’s a first for everything at Joseph Ash Galvanizing!

Folly Farm Adventure Park and Zoo is based in Pembrokeshire, Wales. It was opened in 1988 after being converted from a former dairy farm, and now receives over 400,000 visitors a year.

The park is home to many different types of animals, from lions to penguins and giraffes, and in October 2015 it welcomed two black rhinos to its family.

The rhinos are very rare animals – with fewer than 650 left in the wild – and they have been made welcome at Folly Farm with a brand new rhino enclosure.

The rhino enclosure features a bespoke house that includes four indoor facilities and straw beds for the rhinos to sleep on. The house is called the Kifaru Reserve, and it has separate interlinking rooms for the rhinos, as they are quite solitary creatures, not often enjoying the company of other rhinos.

Joseph Ash Galvanizing and Folly Farm

The new enclosure is a flagship exhibit and an exciting chapter for Folly Farm. It has also been an exciting project for Joseph Ash Galvanizing who was tasked with the job of galvanizing the steel frames for the rhino enclosure.

Folly Farm fabricated the steel frames themselves at their in-house fabrication unit. And Joseph Ash Bridgend and Joseph Ash Telford galvanized the 14 tonnes of steel.

As the local plant to Folly Farm, Joseph Ash Bridgend collected all the steel and galvanized the smaller pieces. The Joseph Ash Telford plant then collected the steel from Bridgend before dipping the larger pieces into their larger galvanizing bath. Once this process was complete, the steel was delivered back to Wales, where the Joseph Ash Bridgend team placed everything onto Joseph Ash Galvanizing trucks and drove it back to Folly Farm.

Folly Farm chose to contract the work to Joseph Ash Galvanizing not only because Joseph Ash Bridgend was local, but also because Joseph Ash Galvanizing provides such a flexible service that not only gets the job done to a premium quality, but also takes all the hassle out of transport and supplier logistics.

Rhinos’ home protected for many years to come

Galvanizing improves the appearance, as well as protects and prolongs the life of steel, so we hope the rhinos will enjoy their new surroundings for many years.

You can find out more about Folly Farm on their website or their Facebook page.

Next page