Distance no problem for football pitch goals

In the burning heat of Abu Dhabi, in the shadows of the Sheikh Zayed Cricket Stadium, sits a new football training ground called ‘Soccer City’. It’s a facility opened by the Abu Dhabi Sport’s Council to provide world class football training for aspiring players.

Proving that distance should never be a problem, one of our UK customers fabricated fences for the facility. Before the steel made its way to the Middle East, the Company asked Joseph Ash Bilston to galvanise it.

CLD Fencing Systems has been in business since 1969 when it was set up by the Wells family. It is now the largest manufacturer and supplier of rigid mesh fencing systems and security gates in the UK. Still owned by the same family it produces fencing from its facility in Sandbach, Cheshire, and also has offices in London, Sydney and Dubai.

In conjunction with Wallbank Fencing who project managed the job on-site in Abu Dhabi, the Company was tasked with manufacturing different types of bespoke fencing for eight five-a-side pitches for the new state-of-the-art football facility. The requirements of the project needed to be:

- Adaptable.

- Strong and robust.

- Have the ability to separate the eight pitches and prevent balls entering play in other pitches.

- Integral goal mouths to help reduce space in the complex.

- Able to withstand the harsh environment of weather in such a hot location.

As part of the project CLD Fencing Systems manufactured fences ranging from:

- Dulok Sports: a double wire fencing system with twin 8mm horizontal wires offering a strong fencing panel to prevent damage from impact.

- Ball Stop Netting: which provides a low-cost solution to pitch demarcation that can be used to heights of 8m.

- Lockmaster Swing Gates: offering a secure entry and exit system to each pitch.

Protection from the elements

To protect the fences, CLD Fencing Systems asked Joseph Ash Galvanizing to provide them with a galvanised finish. Galvanizing is important because it provides a long-life, low-maintenance corrosion protection which safeguards steel from atmospheric attack, especially in such environmentally harsh locations as the Middle East. Our Bilston plant managed the job and, in total, galvanised about 25 tonnes worth of steel.

Rob Nelson, Divisional Manager at Joseph Ash Bilston said: “As a UK company, we’re regularly galvanising steel for motorways, infrastructure, railways, and buildings up and down the country and it’s great to see our work as we travel. It’s exciting to work on projects that also end up in distant locations too however, so it was great to assist CLD Fencing Systems on this job.”

Stewart Plant, Director of Marketing from CLD Fencing said: “As the fences would end up over 5,000 kilometres away, there was no room for manufacturing error. The project had to be perfect first time. We chose Joseph Ash Galvanizing to protect the steel because we knew they would be a reliable partner and deliver a first-class service.”

Next page

Motorway barriers ready after being galvanized by Joseph Ash Chesterfield.

With a potential Brexit just around the corner, a traffic-management plan to minimise disruption for motorway travellers and Cross-Channel lorries may soon get reactivated. The plan – called Operation Brock – is a set of measures between junctions 8 and 9 of the M20 that will enable the motorway to stay open in case Brexit causes chaos to services across the English Channel and Kent.

Operation Brock – a replacement to Operation Stack from 2008 – includes 20 miles of steel that creates separate lanes on one side of the motorway for lorries to queue for the Channel Crossing, as well as a contraflow on the London-bound side of the motorway so that other vehicles needing to travel to Kent, do not get caught in the disruption.

The steel is made up of Vehicle Restraint Systems (barriers), transitions and end terminals and they were fabricated by Hill and Smith Ltd (part of Hill and Smith Holdings, Joseph Ash Galvanizing’s parent company).

Joseph Ash Chesterfield hot dip galvanized the steel – 100 tonnes worth – to protect it from the elements, i.e. wind, rain etc which would otherwise lead to rust and erosion.

The barriers were originally put in place in March 2019 in preparation for the 29 March Brexit deadline but were deactivated after a stay of leave was negotiated with Brussels. With the Supreme Court’s ruling yesterday on the illegal prorogation of Parliament, we’re not sure what the future holds for Brexit, but the barriers are in place should Operation Brock get activated again.

_____________________

For information on the design and fabrication of all types of steel restraint barriers and infrastructure products, contact Hill and Smith.

Joseph Ash Galvanizing is also the first port of call for all types of steel protection: galvanizing, shot blasting, powder coating and duplex coatings.

For updates on Operation Brock, visit the Highways England website.

Next pageA UK steel industry backed project to rebuild a hurricane-hit primary school is nearing completion in the Caribbean.

Dorset-based John Reid & Sons Ltd (REIDsteel) is leading a consortium of UK businesses – including Joseph Ash Galvanizing – which have joined forces to help reconstruct the Enis Adams Primary School on Tortola in the British Virgin Islands.

Other businesses include Tata Steel, National Tube Stockholders, Euroclad, Ayrshire Metal Products, BAPP, Powell Gee & Co Ltd, Kestrel Liner Agencies and Meachers Global Logistics.

REIDsteel commercial director Tim Cook has just returned from Tortola where he saw how work was progressing under main contractor Newton Construction Co Ltd.

Tim said: “It was great to see the new school in person.

“All of the steelwork has gone up and work is going well as it nears completion. The school is being rebuilt to modern standards and requirements with disabled facilities, and an additional second floor.

“As well as seven classrooms on the ground floor, it will have a science lab, IT Suite, library, large seminar room on the second floor plus a medical room.

“The school will be much improved on the previous building and will create a real legacy for the future.”

The school was completely destroyed when hurricanes Irma and Maria swept through Tortola in October 2017.

Virgin Islands businessman Peter Haycraft, a longstanding client of REIDsteel with his former business Road Town Wholesale, has pledged his own money for the reconstruction.

REIDsteel, based in Christchurch, Dorset, with 130 employees, designed and supplied steelwork, and rallied its suppliers to support the project too.

Now they are to send keepsakes to Tortola for a time capsule to be buried at the school before it is due to open to pupils in the Autumn.

Hesketh Newton, managing director of Newton Construction Co Ltd, said: “The school is taking shape with every passing day and will be superb once finished.”

Mr Haycraft said: “It is gratifying to see the Enis Adams school rise from the rubble as our community works to put the devastation of the hurricanes behind us.”

REIDsteel designed the new school to withstand 185 mile per hour winds and earthquakes based on Unified Building Code Occupancy Category III and IV.

All of its 26 buildings in the British Virgin Islands survived the hurricanes of 2017 with only superficial damage.

Mr Cook saw firsthand how the company’s structures had stood strong while others collapsed around them during his recent visit.

Others involved in the Enis Adams project are architect AEMC Architectural Services, Civil Engineer AEC Consulting Engineers Ltd, Electrical Barry’s Electrical Services, Reliable Plumbing, S & D Security, and the British Virgin Islands Ministry of Education and Culture.

Tata Steel has helped with supply of floor decking and giving Colorcoat ® pre-finished steel for roofing, whilst Cardiff based Euroclad has given finished roof materials.

Thirsk-based National Tube Stockholders has given steel tube and steel hollow sections, Joseph Ash Galvanizing has hot-dip galvanised the structural steelwork and Ayrshire Metal Products has given secondary steel cold rolled purlins.

Barnsley-based BAPP has supplied industrial fasteners and bolts, Powell Gee of Shrewsbury has supplied fixings for floor decking and the external cladding envelope.

Kestrel Liner Agencies has helped with shipment and Meachers Global Logistics with shipping services.

Next pageArt Metal is a family run Blacksmiths based in Bromsgrove, Worcestershire. Combining fabrication and craft skills, they provide bespoke designer metalwork for a range of customers – residential, commercial and industrial.

Their work includes gates, fences, railings, arches, staircases and bridges, as well as water features, sculptures and public works of art.

A recent commission from one of their clients was a request to fabricate a large centre piece garden feature in the shape of a thistle.

The 10 ft high and 5 ft wide flower weighed over 250kgs, took four weeks to make and looked elegant and majestic once sculpted.

The sculpture was crafted from mild steel, and to protect it from the elements for many years to come, Art Metal turned to Joseph Ash Walsall to get the artwork galvanised. Galvanizing is important for steel because it provides a long-life, low-maintenance corrosion protection which safeguards steel from atmospheric attack.

Paul Hudson, Sales Manager from Joseph Ash Walsall said: “It was a pleasure to galvanise the steel thistle. Thistles can often be overlooked in their beauty compared to other flowers, but Art Metal have done justice to their spikes and elegance.”

Adam Barrett from Art Metal said: “We enjoyed fabricating this garden centrepiece for our client and wanted to ensure its beauty would be enjoyed for many years to come by sending it to Joseph Ash Walsall for a galvanised finish. Our client loves the finished sculpture and has now asked for some matching thistle styled gates, which we’ll fabricate later this year.”

Next pageLawley and Overdale Parish Council, based in Telford, are very active each year in commemorating local residents who have contributed as military and civilian servicemen and women in the two World Wars and later conflicts. A great example of this includes placing 200 poppies on lampposts across the Parish every year.

A recent – and perhaps grander – project to remember the sacrifices, includes a permanent structure for the area: stunning hot dipped galvanized steel poppies, a memorial and a roll of honour. The installation was a vision of the Parish Council for about 3-4 years, and recently Art.Fabrications – with some help from Joseph Ash Walsall – made it possible.

Art.Fabrications is a specialist fabricator and installer of metal sculpture and artwork. Based in Nuneaton, Warwickshire, it was the perfect company for the project as its team members are able to spend time understanding the original concept and idea and produce a piece of art or sculpture that authentically captures the original vision.

After being let down by a number of other companies, members of Lawley and Overdale Parish Council met with Art.Fabrications, commissioned the project and the team got to work.

Art.Fabrications made the main structure for the poppies from sheet mild steel, which was zinc sprayed and painted. The actual poppies themselves – weighing 90kgs – which run-up one side and onto the top of the structure were fabricated and then sent to Joseph Ash Walsall for galvanizing.

Mick Jackson from Joseph Ash Galvanizing said: “We have worked with Art.Fabrications on a number of projects over the years, galvanising their steelwork to ensure a good quality finish and protection from the elements which would otherwise lead to corrosion and rust if left untreated. We were thrilled to galvanise the stunning poppies for Lawley and Overdale Parish Council, at our Walsall plant. Our treatment should ensure the local residents can enjoy the poppies for many years to come.”

Andy Langley from Art.Fabrications said: “We love listening to someone’s vision about an art installation, understanding their reasons behind the project, and then taking it on and getting to work. We were very happy to fabricate such an important piece of work for Lawley and Overdale Parish Council, partly because they’d had the vision for a good few years, but also because it’s so important to commemorate our servicemen and women. We hope it is a structure that will provide comfort to people in the local community who have lost someone in the two Great Wars or more recent conflicts.”

The hot dipped galvanized poppies will be a key focus for this year’s Remembrance events in September.

Next page

Hot dipped galvanized steel for a new clubhouse at Harlesden Community Garden Project

In 2013, an open space and playground for the local community in Harlesden had become an area that was uninviting and known for anti-social behaviour. A community consultation was held to see how to improve the land. As a result, an organisation called the Friends of Harlesden Town Garden (FHTG) was created (in partnership with Crisis Brent and Brent Council) to improve the parkland with a new play area for children, a green lawn and wild flower area, a multi-use games area and raised bed allotments. As part of the project, FHTG also wanted to build a community Clubhouse. A number of volunteers, businesses, charities and educational facilities – including Joseph Ash Medway, Storp Weber Architects, the Bartlett School of Architecture, Lafarge, F.H. Brundle, and Lathams – stepped in to help with construction and funding.

The Clubhouse – which is currently under construction – will sit at the heart of the new community garden. Designed by local Brent Architects Storp Weber – as part of an on-going research and community outreach activity at the Bartlett School of Architecture – the building will act as a central hub where visitors and gardeners can go for tea and biscuits or conversation. It will also be used as a multi-functional, eco-friendly venue for workshops, events and meetings.

The main shell of the Clubhouse is a shipping container surrounded with a steel frame and timber panelled perimeter. Lafarge provided the insulation, Lathams provided the timber, and F.H. Brundle provided the steel frame which Joseph Ash Medway was only too happy to galvanize.

Joseph Ash Medway collected 72 pieces of steel in total, collectively weighing 842kg, from the Bartlett School of Architecture, galvanized it and delivered it to Harlesden. The hot dip galvanized finish will protect the steel from the elements – rust and erosion – for the next 25 years.

Tim Palmer at Joseph Ash Medway said: “The Harlesden Community Garden Project is a great initiative where people can work hard, play hard, exercise, learn new skills, improve their area, and meet new people. The Clubhouse acts as a focal point for the garden and we were happy to donate our services when the School of Architecture approached us. It has been great to work in partnership with Storp Weber, Lafarge, Brundle Steel, Lathams and the students at the University. It’s also amazing to see what can be achieved when many groups – communities, organisations, businesses – pull together.”

The Clubhouse project has been taking shape and is due to be completed in July. The groundworks will then be added, and the grand opening should take place in August or September. We’ll keep you posted on future developments and share posts on the Joseph Ash Instagram account.

___________________

You can also read about the project on the Bartlett School of Architecture webpage.

There is also a short film produced by Saint Gobain Isover about the building.

Next page

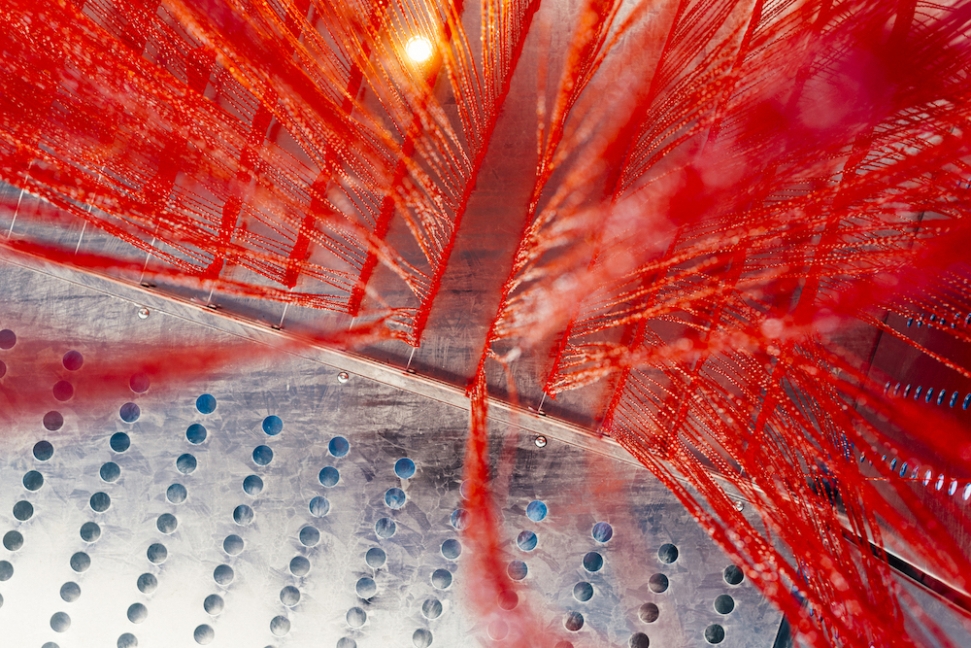

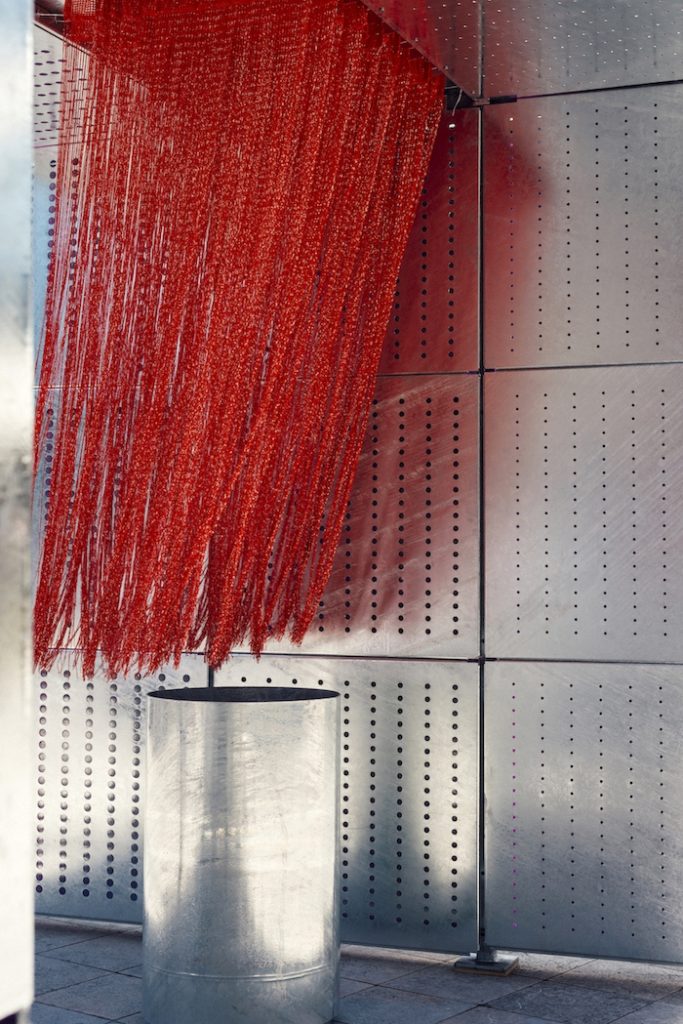

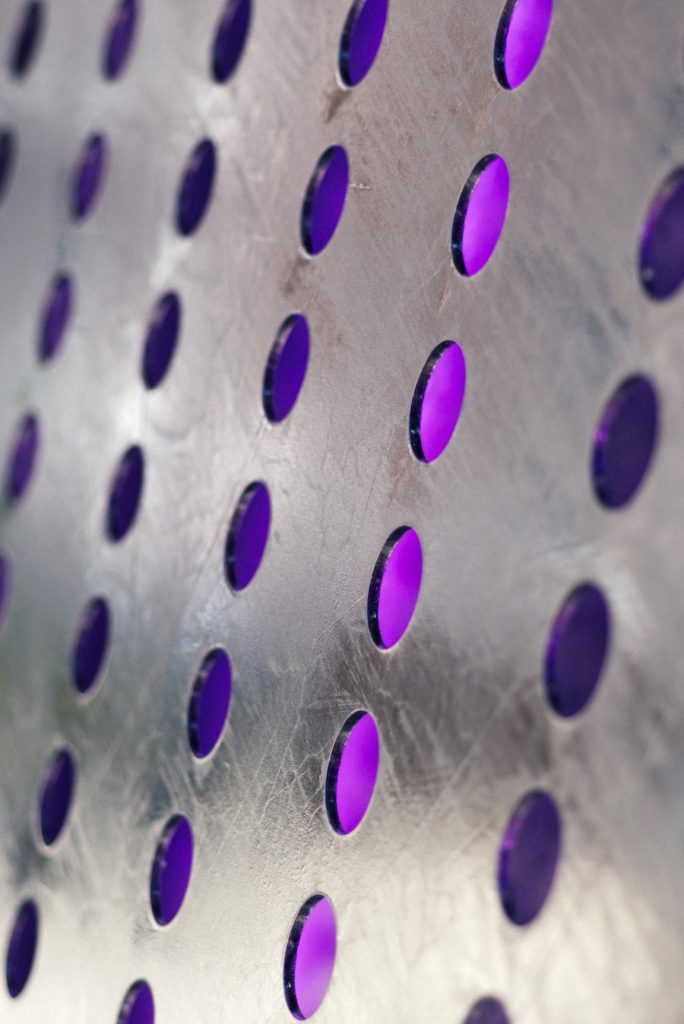

‘BE, Well’ at Clerkenwell Design Week

We recently spent four days at Clerkenwell Design Week, showcasing the aesthetic beauty and sustainable benefits of galvanized steel, with the ‘BE, Well’ installation in St. John’s Square. The 9 x 3 x 4m pavilion shaped structure was built as part of a collaborative project between partners Haines Watts (who sponsored the project), WR-AP Architecture, John Cullen Lighting, Lionweld Kennedy, Berry Systems, and Joseph Ash Galvanizing. The event was a great success, with many people stopping by to interact with the installation and leave their ‘thought of the day’ in the well. In a week forecast for rain, we were also amazingly lucky with the weather. The sun shone all week, the steel glistened, and visitors to the event were able to enjoy all the Clerkenwell designs, inside and out, at their very best.

As we’ve now come to the close of such an amazing project, we thought we’d share some of the thoughts behind the installation from Sean Weston and Max Rengifo at WRAP Architecture, the architects leading the project.

Why were you attracted to the project?

As an emerging architecture practice, we were excited to participate in Clerkenwell Design Week – such a renowned international design festival – and be given free reign on the design content by our sponsoring partners Haines Watts. Also, many of the installations at Clerkenwell Design Week in previous years had focused on the craftsmanship synonymous with the area. With our design we felt it was an interesting opportunity to focus on a more finite aspect of design and to work with one specific material – galvanised steel – to showcase its potential to the design world and to allow an alternative type of craftsmanship to be featured.

Can you describe the installation and its defining features?

The ‘BE, Well’ pavilion is an investigation into the design potential of galvanised steel. In an age where sustainability is on the agenda of all design disciplines ‘BE, Well’ showcased the whole life longevity and potential beauty embodied in the galvanising process. The pavilion took visitors on a journey from utilitarian building products through to bespoke architectural elements, all showcasing the detailed beauty of galvanising.

As Clerkenwell Design Week was celebrating its 10th anniversary, the pavilion featured a galvanised steel well as its centerpiece. We felt this was important as it would remind visitors that Clerkenwell originally had a well (hence the name!). The well within our installation acted as a place where visitors were asked to comment on the design industry, or simply leave their ‘thought for the day’.

What were your biggest challenges during the project?

The biggest challenge we wanted to overcome was to ensure that a material – galvanised steel – that is usually used in either a utilitarian or industrial manner could be showcased with finesse and elegant detailing to promote its innate aesthetic properties. We believe we achieved this with the ‘BE, Well’ installation.

What is the meaning behind the pavilion’s name ‘BE, Well’?

The ‘BE, Well’ name represented all the good things that the pavilion characterised: the protection and long-life expectancy that galvanising provides to steel; and a new physical well for Clerkenwell to attract positive thoughts about the design industry, Clerkenwell Design Week, or simply good ‘thoughts for the day’.

__________________________

Partnership roles

Haines Watts London, a top UK accounting firm, is sponsored the project. With decades long experience of working with some of the UK’s most prestigious architecture firms, they wanted to share their support for the architecture industry by sponsoring an up-and-coming young architecture practice to design the installation.

They chose WR-AP Architecture as the designers, a young London-based practice set up by Sean Weston and Max Rengifo in 2018, which specialises in creating beautiful buildings with delightful, memorable and enjoyable experiences for their clients and the environment.

As the installation was made from steel, Joseph Ash Galvanizing protected the metal using a batch hot dip galvanizing process from one of our plants.

Joseph Ash Galvanizing is part of Hill & Smith Holdings PLC. Two other companies within the Hill & Smith group – Berry Systems and Lionweld Kennedy – also made up the partnership. Berry Systems fabricated the steel, and Lionweld Kennedy fabricated the mesh grating.

The final company in the collaboration was John Cullen Lighting, the award-winning lighting specialist, who enhanced the installation with a variety of stunning lighting techniques.

Next page

Metal Dynamics is a welding and fabrication company based in North West London, producing the finest quality bespoke metalwork for their clients.

Known for their workmanship and quality, the company was recently approached by the homeowners of a property in Wimbledon who wanted some railings for the front of their garden. The clients wanted something different and commissioned Metal Dynamics to produce something new and beautiful.

Lee Richardson and Matt Aldhouse at Metal Dynamics set to work designing and fabricating the railings from mild steel creating 80 x 80 x 3mm box sections for the top and bottom bar and posts, and 50 x 50 x 3mm ERW box sections for the infill bars. All the infill box sections were internally vented, ready for the next stage of the process: steel protection.

Protecting the steel

Workmanship this striking needs to be protected from the elements. This can be achieved by applying a long-life, low-maintenance galvanised coating which safeguards steel from atmospheric attack. For this part of the process, Metal Dynamics booked Joseph Ash Medway – who they use for the majority of their steel protection – to shot blast, hot dip galvanize and powder coat the steel.

The final railings – powder coated in RAL7024 grey – weighing in at 240kg, and 815mm high by 5995mm in length were finished and installed by Metal Dynamics and the client was very happy.

Lee Richardson at Metal Dynamics said, “We are very pleased with the finished job and how these railings look. It is nice to do something a bit different. We have been using Joseph Ash for our galvanised and powder coated metal work for many years and the quality of their work is very good.”

Tim Palmer at Joseph Ash Medway said: “We have treated a number of projects for Metal Dynamics and we’ve always admired the steelwork they send to us. It was a pleasure to work on these railings for Lee and Matt and it’s great to see photos of the finished steel at its final destination. The railings look particularly impressive. Definitely an ace job for their Wimbledon customers!”

Next page

Tim Palmer, Divisional Manager at Joseph Medway, speaks to Steelo about the process of hot dip galvanizing.

Steelo is a structural steel fabrication company based in Hounslow. Originally set up as a one-man venture in Isleworth by founder Michael Krajewski, the company has grown in size to over 20 people with a 12,000 square foot plant near Heathrow.

The company fabricates everything from beams to frames to posts and regularly uses Premier Galvanizing (a Joseph Ash Galvanizing company) to protect the steel with a galvanized finish.

At an event last year, Krajewski interviewed Joseph Ash Medway‘s Divisional Manager, Tim Palmer, to find out about the process of galvanizing. The video is available on the Steelo website. See it here.

Steelo is a great company to supply services to. Thank you for the video and recommendation!

Next page

Time and Tide for Winter Lights, by Paul & Pute

Canary Wharf in London has been hosting a Winter Lights Festival for the public every January for the last five years. It is a magical event featuring beautiful light installations, which “draw upon state-of-the-art light technology to deliver spectacular artworks, installations and experiences – many of them interactive or responsive”[1]. This year’s event was special to the Joseph Ash Group, as it featured an installation hot dip galvanized by our Premier Galvanizing Corby team.

The installation – called ‘Time and Tide’ – was designed by artists Paul & Pute. Paul (from Manchester) and Pute (from Bangkok) met whilst studying for their Masters in Sweden at a Technology College.

‘Time and Tide’ is a mixture of architectural and lighting skills, built using steel bases and a central pillar, plus paper drinking straws and UV light from three Chauvet Professional Colordash PAR H12IP wash fixtures.

Because the Winter Lights 2019 theme centred around sustainability and environmental issues, Paul & Pute wanted to design an installation which “celebrated the elegance of technology, [but] also served as a cautionary sign, reminding people to guard against its excesses. With an alluring shape evocative of an hour glass, the structure symbolised that the ecological timeclock is running out… [However] it also offered hope along with its solemn warning. The geometric web of strings that made up the structure’s surface was adorned with patterns created with paper drinking straws to remind people that there is an earth-friendly alternative to plastic models.” [1]

“The paper straws were also illuminated with UV light, giving them a vibrant glow, to symbolise how our planet can become more vital and alive when ecological balance is restored.”[2]

A13 Steel Ltd and Premier Galvanizing

‘Time and Tide’s’ steel bases and pillar were fabricated by A13 Steel Ltd, using designs supplied by Paul & Pute. Each base was about 2-2.5m in diameter and the central pillar was about 4m high.

To protect the steel bases A13 Steel Ltd asked Premier Galvanizing Corby to galvanize the steel. Galvanizing is important for steel because it provides a long-life, low-maintenance corrosion protection which safeguards steel from atmospheric attack.

A13 Steel Ltd have been a good customer of Premier Galvanizing Corby for a number of years, and regularly ask the team members there to treat their steel.

Premier Galvanizing Corby also managed the collection and delivery of the steel on behalf of A13 Steel Ltd.

Here are some photos of the steel being galvanized at the Premier Galvanizing plant, and at its final destination as part of the complete installation.

John Frankland, Sales Manager at Premier Galvanizing said: “Once the project was complete and the lighting festival was underway, I was lucky to be able to visit London and see the installation amongst all the other stunning works of art scattered throughout Canary Wharf. We’re always happy to work on projects for A13 Steel Ltd, and we were particularly thrilled to be a part of this project.”

To see more photos of the ‘Time and Tide’ – whilst being galvanized and at its final destination in Canary Wharf – click here.

[1] Winter Lights Festival website: https://canarywharf.com/arts-events/events/winter-lights-2019/?instance_id=

Next page