Bike racks and accessibility ramp for modern student living

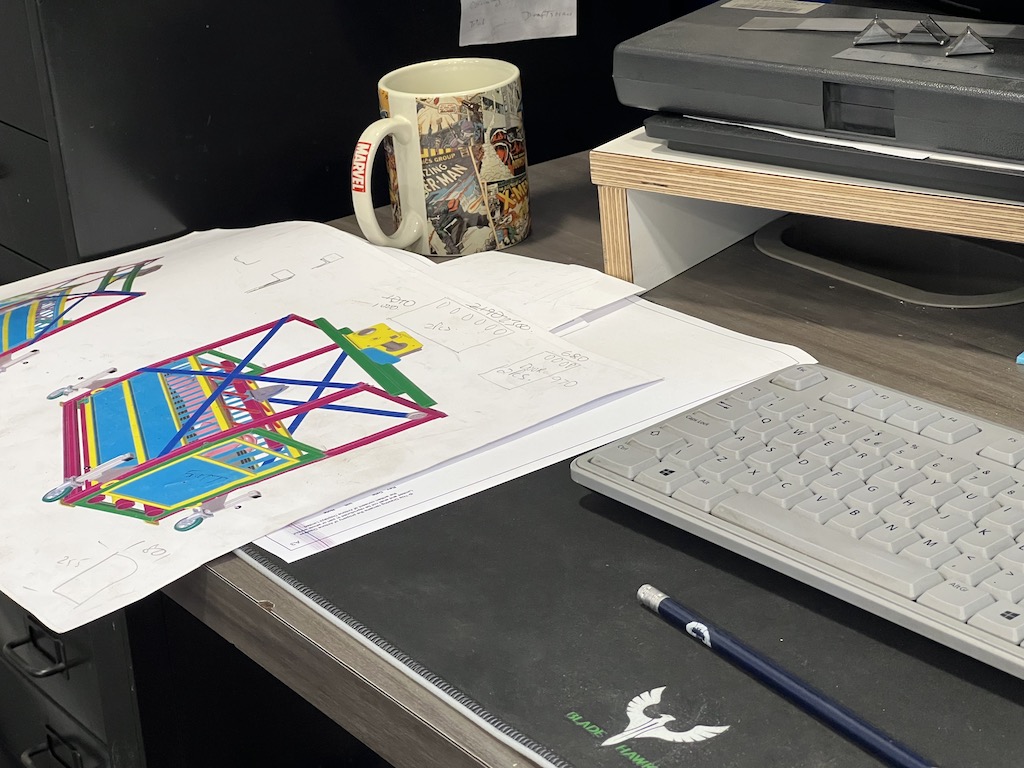

GBT Steelwork, a leader in bespoke steel fabrication, recently completed an extensive project for Urban Nest, a premier student accommodation provider in London. The project involved producing hundreds of steel bike racks for four of Urban Nest’s properties across the city and fabricating a disability access ramp for the Battersea property. To ensure maximum longevity, GBT Steelwork collaborated with Joseph Ash Galvanizing to protect the access ramp and 300 bike racks with a long-lasting hot dip galvanized finish.

Meeting the needs of modern student living

Urban Nest’s properties, known for their modern design and convenience, cater to the diverse needs of students living in London. The addition of these bike racks outside the properties shows their commitment to promoting eco-friendly transportation while enhancing the functionality of their accommodations.

As well as the bike racks, a new disability access ramp was designed for the Battersea property to ensure accessible accommodation for residents and visitors, adhering to the highest safety standards.

The role of hot dip galvanizing

GBT Steelwork chose Joseph Ash Medway to hot dip galvanize the steel bike racks and accessibility ramp. Hot dip galvanizing was chosen as the steel protection method of choice as it is an effective method of protecting steel against corrosion.

The galvanizing process involves immersing steel in molten zinc, creating a robust protective coating where the zinc metallurgically bonds to the steel. This method provides several key benefits that are particularly valuable for urban infrastructure projects:

Corrosion resistance

The primary benefit of hot dip galvanizing is its enhanced corrosion protection for steel, including in outside environments. The zinc coating protects the steel from rust and weathering, making it ideal for the bike racks and ramp.

Longevity

Galvanized steel has a significantly longer lifespan compared to untreated steel, ensuring the bike racks and ramp remain functional and protected against visually unappealing rust for decades. It also means the racks and ramp won’t need to be re-coated and replaced as frequently, saving disruption on downtime for the residents.

Cost saving

Thanks to its increased longevity and protection against corrosion, there are fewer costs from re-coating, maintaining, and replacing the steel.

Promoting sustainable and inclusive living

The bike racks and disability ramp are more than just functional additions; they reflect Urban Nest’s vision for sustainable and inclusive student living. By encouraging cycling, Urban Nest helps reduce carbon emissions while promoting a healthy lifestyle among students. The accessibility ramp, on the other hand, ensures that no resident or visitor is unable to access the property.

Hot dip galvanizing fits into the principles of a circular economy and is an ideal choice for companies who are mindful about sustainability.

A step forward in urban development

Andy Thompson from GBT Steelwork said “This project highlights GBT Steelwork and Joseph Ash Galvanizing’s ability to deliver durable, sustainable, and aesthetically pleasing solutions for modern urban challenges. It’s great to be able to work on projects that are not only aesthetically pleasing and inclusive, but also practical and durable.”

Joseph Ash Galvanizing has protected the steel for several GBT Steelwork projects over the last few years, including some balconies for a prestigious Knightsbridge apartment. The partnership was great for this project, as GBT Steelwork’s expertise in steel fabrication and Joseph Ash’s galvanizing process ensure that Urban Nest’s investment is practical and sustainable.

GBT Steelwork can fabricate all types of architectural and structural steelwork, anything from steel beams to gates, bike racks to agricultural pens, balconies to staircases. For more information about GBT Steelwork’s fabrication services contact Andy Thompson on aftommo@hotmail.co.uk or 07872507973.

Next pageSokari Douglas Camp’s ‘The Three Graces – The Dialogue’: galvanized and powder coated by Joseph Ash Medway

On Sunday 30th June, in the Kleurenbuurt neighbourhood of Zaandam, Netherlands, a powerful sculpture by artist Sokari Douglas Camp, was unveiled. Named The Three Graces – The Dialogue, the artwork was created in commemoration of Keti Koti.

Keti Koti, meaning “broken chains,” is an annual event held across the Netherlands to mark Emancipation Day in Surinam, a former Dutch colony. The celebration, held on 1st July, commemorates the abolition of slavery in 1863 and serves as a moment to honour those who lived in bondage while reflecting on the significance of living in freedom. In this context, The Three Graces takes its place as a focal point for healing the wounds of the past and encouraging dialogue about a shared and often painful history.

The sculpture and its meaning

Sokari Douglas Camp, renowned for her artistic work with steel, designed The Three Graces – The Dialogue as a symbol of resilience, healing, and unity. The sculpture draws direct inspiration from an 18th-century piece by abolitionist William Blake titled Europe Supported by Africa and America. (A print of this can be seen in the library at the Victoria and Albert Museum.) Blake’s piece depicts three women – an African woman and American Indian woman shown unclothed, and a European woman, partially clothed. The difference in clothing signifies the imbalanced power dynamics of that era. Sokari, however, sought to reclaim and reframe this narrative.

In her vision, the three figures are African women, fully clothed, sitting as equals. Their elaborate and voluminous skirts, a nod to the fashion of Surinamese women, are rich with cultural meaning. Surinamese women, known for wearing multiple layers of clothing at once, developed this style partly due to the lack of storage space but also as a protective measure against the risk of assault.

The Three Graces – The Dialogue shows the women engaged in an imagined conversation about their shared history of slavery and the continuing struggle for reparations and justice. This dialogue is a visual and symbolic centrepiece for Keti Koti’s annual remembrance and reflection.

Craftsmanship and preservation

The sculpture was welded from 3ml sheet steel, blending the industrial toughness of metal with the fluidity and grace of human forms. Joseph Ash Galvanizing was commissioned to galvanize and powder coat the work to ensure its durability and protect it from the elements. The galvanizing process involved coating the steel with a layer of zinc, providing a robust and reliable defence against corrosion. This ensures that the statue, much like the history it represents, will endure for generations.

The unveiling and community reception

The unveiling ceremony in Kleurenbuurt attracted around 200 people, including Sokari Douglas Camp herself. The community gathered in a spirit of remembrance, reflection, and celebration, marking The Three Graces as a focal point of collective healing.

In the tradition of Keti Koti, the piece serves as a catalyst for conversation – an essential dialogue about history, memory, and the need for reparations.

A lasting legacy

Sokari Douglas Camp’s The Three Graces – The Dialogue stands as a testament to the enduring impact of slavery, the strength of those who survived, and the continued efforts toward healing and reconciliation. Its ongoing and permanent presence in Zaandam’s Kleurenbuurt ensures that the story of Keti Koti and the voices it represents will continue to resonate with all who see it.

This piece, galvanized and protected, will remain a lasting symbol of the power of art to inspire reflection, conversation, and healing.

To see more of Sokari Douglas Camp’s work, visit her website.

You can also visit galleries such as the V&A, The Smithsonian Institute and The October Gallery where she has permanent pieces of art on display.

To see more of Sokari’s work galvanized by Joseph Ash, read Celebrating the Heritage of Carnival and Jonkonnu.

Special mentions

When Sokari fabricated The Three Graces – The Dialogue she had help in her studio from her assistant, who deserves a mention. His name is Luke Chin-Joseph.

A company called MDM Props also deserves a mention as they transported the finished sculpture from Joseph Ash Medway to The Netherlands. MDM Props deals in art manufacture, scenic construction, and prop making, and regularly works with both Sokari Douglas Camp and Joseph Ash Galvanizing.

Finally, a special mention goes to the municipality of Zaandam who made this commission possible.

Next pageJoseph Ash Galvanizing recently collaborated with GBT Steelwork, a family-run steel fabrication company based in South Ockendon, Essex. Under the leadership of Andy Thompson, GBT Steelwork took on an ambitious project to fabricate 26 balconies for a high-end apartment block in Knightsbridge, London.

The project scope

Commissioned by Collins Construction, the project demanded exceptional quality and precision, reflecting the upscale nature of Knightsbridge. The balconies, weighing approximately 13 tonnes in total, needed a robust and durable finish to ensure their longevity and resilience against the elements. To achieve this, GBT Steelwork relied upon Joseph Ash Galvanizing’s Medway plant to hot dip galvanize some of the steel balconies.

Galvanizing process

Hot dip galvanizing was the coating method of choice thanks to its ability to provide a long-lasting, corrosion-resistant finish. The galvanizing process involves immersing the steel in a bath of molten zinc, creating a tough, protective layer that bonds with the steel at a molecular level. This scientifically-backed coating method ensures its reliability at protecting steel against atmospheric attack.

Our team at Joseph Ash Medway undertook the galvanizing process with meticulous attention to detail, ensuring that each balcony met the highest quality and durability standards. The hot dip galvanizing not only enhances the steel’s resistance to rust and corrosion but also provided an aesthetically pleasing finish, aligning perfectly with the high-end requirements of the Knightsbridge development. Galvanized steel is reliably used for construction and infrastructure projects thanks to its corrosion-resistant properties.

Transportation and installation

Once galvanized, the balconies were carefully loaded and transported to the Knightsbridge site, ensuring they arrived pristine and ready for installation.

Andy and his skilled team at GBT Steelwork then undertook the installation process. The whole project spanned nine weeks. Each balcony was meticulously fitted, contributing to the apartment block’s design and functionality. The galvanized finish not only provided the necessary durability but also complemented the building’s architectural design.

Working collaboratively

Galvanizing expertise, combined with intricate steel fabrication and installation, ensured balconies were delivered that are both beautiful and built to last.

Andy Thompson’s leadership and his team’s dedication were crucial in bringing this project to fruition. Their commitment to excellence ensured that the balconies not only met but exceeded the expectations of Collins Construction and the residents of the Knightsbridge apartments. We were proud to contribute to this project, and help protect these well-crafted balconies for many decades to come.

Your trusted galvanizing partner

Joseph Ash Galvanizing is trusted by many companies to deliver exceptional hot dip galvanizing, powder coating, and spin galvanizing services.

If you have a steel coating requirement, get in touch with one of our nine UK sites today.

Next pageThe RHS Chelsea Flower Show is an annual show to see cutting-edge garden design, new plants, and garden ideas, drawing a global crowd year on year. This year it took place from 21st-25th May 2024.

Ian Gill Sculpture, an award-winning metal sculptor based in Lincolnshire, is a regular attendee at these shows, crafting beautiful horticultural stands to be featured and displayed. Premier Galvanizing Hull has been proudly galvanizing Ian’s sculptures for 3 years, and were delighted to assist with Ian’s display at this year’s show.

We had the opportunity to speak to Ian about this year’s show, his inspiration for the stand, and why he can rely on Premier Galvanizing to hot dip galvanize his work.

About the project

Ian has been sculpting for over 25 years, and has been fabricating for the Chelsea Flower Show since 2008, attending every show since.

Ian’s stand featured multiple sculptures of different plants and shrubbery, including gunnera (giant rhubard), giant corten fern, and pond reeds. The stand incorporated a mixture of real and steel foliage, and included some stunning water displays. The real greenery was grown by Ian’s partner.

When asked about his inspiration for the project this year, Ian said:

“I got my inspiration for this year’s display from studying organic plant matter and nature. I had a lot of fun manipulating the steel to make it look soft and more like a real plant.

“Gunneras were going to be banned from the show because they were recently classified as an invasive species. But they didn’t know I was going to be bringing one – just one made out of steel instead.

“It took about 6 months total, working 10-12 hours on the project every day. All of my effort went into the display during those 6 months.

“There was about 25 tonnes of materials in total required to build the stand, including the flooring and surrounding materials.”

About this year’s show

2024 marks the 17th Annual Chelsea Flower Show that Ian has featured at.

There were about 250 stands at the show this year, and only around 40 got a 5 Star Tradestand Award by the Royal Horticultural Society.

Ian earned one of these 5 Star ratings during the show this year – an incredible (and well-deserved) achievement.

Some of Ian’s water features were displayed outside of his stand and were featured around the wider show, including a giant cascading waterfall which was displayed on the Malvern Garden Buildings stand.

Premier Galvanizing delivers a high quality finish

Ian started using Premier Galvanizing Hull 3 years ago, when he moved from the south up to Lincolnshire.

Ian recalls having poor experiences with another galvanizing company in the past. Moving up north provided him with an opportunity to find a new galvanizing company who understood the delicate nature of his sculptures, and could reliably galvanize them to a high quality without damaging his craftmanship.

“It’s devastating when you spend 3 months full-time producing a sculpture, just for a galvanizer to mess it up in 30 minutes. But since switching to Premier Galvanizing, I’ve been very happy. The team there are easy to reach out to and I can rely on them to look after my work.

“Talking to other metal artists at these kinds of shows, one of the first things that gets asked is, “Who does your galvanizing?”. Other metal artists often complain about how much of a nightmare it is to find a good galvanizer, and I used to join in with the complaining in those conversations, too. But I can’t anymore, because the quality I get with Premier Galvanizing is brilliant.”

Sustainability

Sustainability is at the forefront of many people’s priorities in recent years. Ian ensures the elements of his stand don’t go to waste.

“I’ll reuse the flooring on the stand as the slabs can be lifted up. I’ll also go on to sell the sculptures to the public after the show as ex-display. My partner will also take the real plants back and replant them to be used in other projects.”

Hot dip galvanizing is a sustainable practice, fitting into a circular economy. The high-quality galvanized finish provided for Ian’s sculptures means that they are protected from corrosion caused by atmospheric attack. The customers who will go on to buy these sculptures can be sure they will last for many years to come; and, should the sculptures need to be recycled, this can be done without loss of properties.

Another good year at the Chelsea Flower Show

Overall, this year’s show was another success, both for Ian and for the Royal Horticultural Society.

When asked about future projects, Ian concluded:

“I’m going to continue to make bigger, better, and crazier projects in the future.” We can’t wait to see them!

Ian Gill is the founder of Ian Gill Sculpture. More photos from this years show, as well as his stands from previous shows, can be found on his website www.iangillsculpture.com. Pictures supplied by Ian Gill.

Galvanized cob horse for heritage recognition in the South Downs

The Changing Chalk project is a multi-partner, multi-project initiative led by the National Trust. The project aims to restore lost habitats, bring histories to life, and provide new experiences in the outdoors.

As part of this project, Changing Chalk commissioned Jake Bowers, artist and blacksmith at Thirsty Bear Forge, to fabricate a life-size cob horse to recognise and celebrate the cultural heritage of “Gypsy, Roma and Traveller” communities in the South Downs. Jake relied on Joseph Ash Medway to galvanize the horse to the best quality, preserving it for many years to come.

The creation of Prissy

Jake took measurements for the sculpture from a real-life model: Winnie the cob, who was the much-loved horse owned by his sister Priscilla. The sculpture itself was decidedly named after Priscilla, too.

Jake also took Priscilla, Queen of the South (as the sculpture had become known) on a nationwide tour so that members of the community and public sector workers could forge part of her mane, feet and tail. Jake noted: “Our presence at Appleby Fair, for example, allowed scores of Gypsies and Traveller community members to create part of the sculpture.”

The community input into the sculpture makes the project even more powerful.

Hot dip galvanizing for an extended lifespan

As Prissy – the shortened name given to the sculpture – was set to live outside in the South Downs, a durable, long-lasting and corrosion-resistant finish was required to ensure it remained protected against the elements for many years to come. Hot dip galvanizing served as the ideal solution, thanks to the extended lifespan it provides for steel. Galvanizing also helps to keep steel looking like new – ideal for preserving the beauty of this symbolic sculpture.

Joseph Ash Medway collected, hot dip galvanized, and returned Prissy back to Jake so that the National Trust could install the sculpture as part of their project.

The outcome

Prissy now resides in the South Downs, serving as a long-lasting reminder of the rich cultural heritage of the communities who help shape these landscapes.

When asked why he chose to galvanize the horse with Joseph Ash Galvanizing, Jake commented:

“The sculpture is so intricate only galvanizing would have reached every part that needed preserving.

“I also love the way Joseph Ash treats works of art with the care and attention to detail that a work of art requires.”

Prissy is the first public sculpture to be unveiled as part of Project Atchin Tan, a community initiative seeking to include the voices of travelling communities on issues of sustainability and global warming. At least two other horse sculptures are planned, largely made from recycled steel and the skills of the community members.

You can learn more about the Changing Chalk partnership on the National Trust website. To discuss the project with the fabricator, contact Jake Bowers at Thirsty Bear Forge.

If you have a galvanizing requirement, get a quote or book a collection with one of our nine UK sites today.

Next pageImagine a museum where creativity knows no bounds, where children, young people, and families can unleash their imaginations and be inspired. Young V&A, the brand-new Victoria and Albert children’s museum, offers just that.

Seeking a fabricator that could make the museum’s exterior stand out, they contacted Factory Settings Ltd to fabricate giant letters to sit on top of the building. Factory Settings, in turn, needed a reliable hot dip galvanizing company that offered a quick turnaround time to increase the steel’s durability and give the museum exterior an eye-catching finish.

Hot dip galvanized by: Joseph Ash Medway

Fabricated by: Factory Settings Ltd

End client: Young V&A

Steel finishing service: Hot dip galvanizing

Young V&A’s requirements

Young V&A is a brand-new children’s museum in London where children, young people and families can imagine, play, and be inspired. The London-based museum wanted to enhance their exterior prior to their opening day on 1st July 2023, and turned to Factory Settings Ltd for help. Factory Settings, also based in London, agreed to fabricate a huge sculpture of V&A’s logo to be displayed on top of the museum – increasing brand visibility and modernising the museum’s exterior.

The museum’s grand opening day was fast approaching, and there was a lot to be done. Factory Settings needed a reliable galvanizing company that offered a fast turnaround time from start to finish. Located in Sittingbourne, Kent, Joseph Ash Medway was the perfect choice for the fabricating company.

The letter’s frames needed to be galvanized to increase the steel’s durability and give it a shiny, clean finish. Galvanizing also makes the steel corrosion-resistant, so the sign stays in excellent condition even in bad weather.

Speedy turnaround times save the day

Sudden delays on steel items and a last-minute change in design meant the deadline was fast approaching without much progress. Factory Settings were reliant on the team at Joseph Ash Medway to adapt to the changing timeframes to ensure the museum’s sculpture was ready for the opening day.

Keen to deliver an exceptional service, the Medway team were swift to adapt to the last-minute collection dates. Joseph Ash Medway’s flexibility to the situation and their quick turnaround times meant that the work was returned to Factory Settings in time for them to finish cladding before the big day.

Young V&A’s grand opening

Young V&A had a successful opening weekend on 1st July 2023.

Factory Setting’s Senior Project Manager was keen to thank the Joseph Ash Medway team:

“Thanks so much for all your help getting the frames back to us quickly so we can hit our install deadline – that made a real difference for us. Can’t wait to see this signage up in the air!”

Well done to Factory Settings Ltd and everyone else involved!

If you’re in London, why not visit Young V&A for a fun and educational day out? Alternatively, if you’re in need of steel fabrication, contact Factory Settings Ltd.

Pictures courtesy of Factory Settings Ltd

Joseph Ash Medway delivers a one-stop-shop service of shot blasting, hot dip galvanizing, powder coating and duplex coatings all from under one roof. Contact the Medway team today to discuss steel treatment projects in London and beyond.

Next pageEvenley Wood Garden (EWG) – located in Northamptonshire – is a beautiful 60-acre woodland garden open to visitors. As well as being able to see plants, unusual trees and shrubs, visitors can also take part in wine-tasting events, plant fairs, craft days, and a host of other fun activities. It’s a lovely day out!

To greet visitors to the park, the team at Evenley had a great idea: placing three giant steel letters – EWG – at the entrance that people would see and engage with as they approach.

Alison O’Hare, Marketing & Events Co-ordinator at Evenley, contacted a local blacksmith company, Baillie & Co, for help.

Adam Baillie from Baillie & Co is a self-employed blacksmith, fabricator, welder, and metalworker. As his studio is just down the road from Evenley Wood Garden, and he often takes part in events there, he relished the opportunity to produce the letter installation.

Adam designed and fabricated each letter to not only be freestanding letters but also planters that can be decorated with stunning floral displays by the gardeners at Evenley.

The letters are solid steel (apart from the hollow base). They are 1.5m high – perfect for visitors to the park to interact with and have their photos taken beside.

Because the letters are steel, they need galvanizing for protection against rust and corrosion.

Adam booked the galvanizing service with Joseph Ash Walsall, where he received excellent service.

Adam was concerned about the letters during the galvanizing process and the potential damage caused by how the letters would have to hang over the zinc bath. However, his concerns disappeared after speaking to Paul Hudson at Joseph Ash Walsall.

Paul happily took the time to explain the importance of vent holes and describe the hanging process.

During these calls, Paul also arranged the collection and delivery of the letters to save Adam from having to manage these logistics separately.

Adam was very pleased with the galvanized finish for the letters. Before delivering them to Evenley Wood Garden, he also applied a final light wash to create a burnished effect.

Adam chose a wash instead of paint to make the letters more environmentally friendly.

The letters are now at Evenley Wood Garden, looking amazing. Adam is looking forward to seeing how the Garden’s visitors react to them. So are we!

_____________________________________________________________________________

About Adam Baillie and Baillie & Co

Adam is a highly experienced metalworker and award-winning blacksmith, with a passion for contemporary design. He thrives in commercial workshops producing superior standards of creative craftsmanship, whilst offering the best in customer and client satisfaction. He provides the following services: bespoke design, conservation and restoration, and general metalworking.

Contact Adam at contact@baillieandco.co.uk for any metalwork needs.

_____________________

Venting hints and tips

For hints and tips on the best way to prepare steel for fabrication, download our free Safe Design for Hot Dip Galvanizing poster.

Next pageGalvanized lift innovation enables safe hoof care

Nestled amongst the rolling hills between Tregaron and Lampeter in Wales is an animal sanctuary called Beneath the Wood. Set up by Sasha Bennett in 2009, it provides a permanent home for dogs, sheep, cats, horses and – as of 2019 – a sounder of pigs.

The pigs (and their subsequent offspring) found safety at Beneath the Wood after they were rescued from an illegal and horrific slaughterhouse in Pembrokeshire. The 53 pigs were living in appalling conditions amongst carcasses and surviving on the entrails of the other slaughtered animals. Some were so desperate they began cannibalising. Some ate car parts, batteries, car doors… anything to avoid starvation.

After being rescued by authorities, the pigs became the subject of a court destruction order as they were not fit for consumption. There was a public outcry, so Beneath the Wood decided to fight for them. After a nine-month legal battle, the pigs (numbering 91 because the males were kept in a DEFRA isolation unit with the females!) were allowed to move to their forever home at the animal sanctuary.

Victory for Beneath the Wood and the pigs! But not without its problems.

Because the pigs had been kept in dreadful conditions at the slaughterhouse, their hooves had grown and, in some cases, become curved and uneven, making it difficult for them to stand and walk. As a result, the pigs needed a much-needed pedicure. But foot care on such heavy and strong animals is challenging. Especially when the biggest pig – Gandalf – is 7ft in length and weighs over half a tonne!

Beneath the Wood turned to Designeering in Leicestershire for help.

Designeering is a design and engineering company which helps people/companies to develop product ideas and bring them to life. The team at Beneath the Wood explained their problem. They told Designeering about animal lifting equipment such as cow hoists. A good idea, but unfortunately not suitable for the pigs. They needed lifting equipment that was strong and modular enough to accommodate different size pigs.

Designeering rose to the challenge and designed, engineered, and manufactured an innovative Pig Lift that can lift the pigs in the air with their feet dangling so they can be treated and trimmed.

They opted for a modular design that can accommodate animals ranging from 150 kg to over 600 kg. The unit is also mobile, electrically operated, and safe for the operator and animal.

As the Pig Lift consists of steel sections, tubes, and laser-cut sheet metal fabrication welded together to form a heavy-duty structure, it needed to be galvanized.

Hot dip galvanizing is imperative because it provides a long-life, low-maintenance corrosion protection, which safeguards the steel from atmospheric attack, which causes rust and weakens steel.

Designeering sent the Pig Lift to Joseph Ash Walsall to be treated with a galvanized coating to prolong the life of the equipment. The team at Joseph Ash were delighted to help such a good cause and donated their time and service free of charge, including collection and delivery.

The Pig Lift was delivered to the animal sanctuary just before Christmas: designed, manufactured, protected from corrosion with a galvanized finish, and ready to enable hoof trimming. The giant boars need hoof trimming first, so they’re being treated, and it’s onto the other pigs.

Sébastien de La Hamayde, Creative Director at Designeering said “We’ve loved working on this project! Sasha Bennett and her team at Beneath the Woods do a fantastic job providing a safe home for all the animals they look after. As for the pigs, despite experiencing trauma at the illegal slaughterhouse where they were found, they are now well looked after and comfortable in their new surroundings. We are proud to have designed equipment to help the Sanctuary continue looking after them.”

Paul Hudson, Sales and Technical Manager at Joseph Ash Walsall, said “Wow! What an amazing project to be involved in. Thanks to Designeering for contacting us and sending the steel to our plant. We were happy to donate our services for such a worthwhile cause. We hope the pigs thrive in their new home and the new lifting equipment gives them some much-needed care.”

______________________________________________________________________________

Beneath the Wood Sanctuary is a not-for-profit organisation. They run solely on public donations, mainly through their Twitter, Facebook, and Instagram social media accounts. They have around 140 animals in their care, ranging from dogs, cats, pigs, horses, and sheep, all rescued from difficult circumstances. They are a small team of dedicated volunteers, just five people keeping the animals fed and cared for, along with occasional volunteer days for extra help on larger projects.

To support the Beneath the Wood team, contact Sasha Bennett via email.

Next page

Throughout July and August, families flocked to resorts in the UK for much-needed rest and relaxation. A popular holiday park in Wales is Trecco Bay. Before the Summer began, Metafab Solutions and Joseph Ash Walsall visited the resort to create a new and exciting space for the holidaymakers.

Trecco Bay in Porthcawl is run by Park Dean Resorts – the UK’s largest holiday park operator – which owns and operates 66 holiday parks. Over the last few years, they have been reinvesting heavily into their parks to improve facilities and accommodation.

The Trecco Bay resort has been the biggest beneficiary of the reinvestment programme – £3.6m – as Park Dean seeks to make it one of their ‘Parks of the future’.

As part of the makeover, Park Dean engaged NBDA Architects – based in Bollington, Cheshire – to design a new, unique space to protect holidaymakers from the weather whilst enjoying the resort’s entertainment and eating areas.

The space is a covered canopy supported by steel struts, including amusements, a bar, giant TV screens, seating areas and coffee shops.

MetaFab Solutions, based in Cinderford, Gloucestershire, is a steel fabricator and welder specialising in the fabrication of bespoke steelwork. They fabricated the steel frame for NBDA Architects and Park Dean.

Fabric Architecture, who specialise in tensile fabric structures, worked with NBDA to design the structure and supply and fit the tensile fabric canopy.

Michael Chung – Projects Director at Metafab Solutions – said, “It was a huge project requiring 60 tonnes of steel for the 64m long, 106m high and 24.6m wide new structure.”

Just as MetaFab Solutions has protected the holidaymakers from inclement weather, Joseph Ash Walsall has also safeguarded the steel.

MetaFab Solutions chose Joseph Ash Walsall to hot dip galvanize the steel, providing a long-life, low-maintenance, corrosion protection to safeguard it from rust.

MetaFab Solutions also chose Joseph Ash Walsall because we provide a hassle-free collection and delivery service for steel.

Paul Hudson – at Joseph Ash Walsall – said, “The new space at Trecco Bay was a great project to work on, especially as we know lots of holidaymakers will enjoy it for years to come.”

Next pageSokari Douglas Camp applauds the Carnival spirit with hot dip galvanized steel sculptures

With London’s most famous carnival taking over Notting Hill next month, we’re showcasing a new art installation by acclaimed artist Sokari Douglas Camp, CBE.

Born in Nigeria and based in London, Sokari has exhibitions worldwide, including at the Smithsonian and the British Museum. One of her most recent was part of Kensington and Chelsea Art Week.

The artwork is a hot dip galvanized steel sculpture of two vibrantly dressed, life-size characters with ornate headgear.

The characters represent key themes:

- Kalabari masquerades from the Nigerian coastal region where Sokari was born.

- The vitality and spirit of the Notting Hill Carnival bouncing back after COVID.

- Jonkonnu revellers in Jamaica in the late 1830s.

Sokari was inspired to create the two characters after researching the origins of the Notting Hill Carnival during lockdown and seeing some Jonkonnu lithographs by Isaac Mendes Belisario.

Jonkonnu was a festival practised during slavery in the Caribbean when plantation workers were allowed a few days off. They celebrated with “exuberant musical masquerades that recalled their African heritage”. (Source)

Sokari saw positivity in the Jonkonnu festivals because even in times of adversity, the revellers danced, sang, showed resilience, and celebrated their heritage.

Likening this to the return of the Notting Hill Carnival after it disappeared during COVID, Sokari had faith that the carnival spirit lives on.

The costumes may have changed since the 1830s – fewer sailors and petticoats, more tiny outfits, lycra and birds of paradise feathered headgear – but celebrating heritage using dance, music, and costumes remains.

Finding ‘good’ in the ‘bad’

Another theme that Sokari explored when creating these sculptures is the notion of ‘finding good in the bad’. When you look at the photos, you’ll see ornate headgear on the two characters featuring tea and sugar cane. With these references, Sokari wants to remind us that Caribbean and African slaves had harsh lives on tea and sugar cane plantations. And yet there’s a dichotomy to this, as tea is often soothing, and sugar is sweet. We should never forget there are many layers of heritage.

_________________________

The making of the sculptures

Sokari made the Jonkonnu sculptures in her Elephant & Castle, London studio by welding, cutting, and bending steel. Joseph Ash Medway – a supplier to Sokari for 15 years – hot dip galvanized the steel to give it a protective coating.

Sokari then covered the sculptures with vibrant coloured car spray back in her studio.

She had just one month to pull the whole project together! But she succeeded.

_______________________

If you’d like to see the Jonkonnu sculptures, they will be outside the Design Museum in London until 30 August 2022, and as part of an exhibit at The October Gallery until 23 July 2022. Sokari is also exhibiting at the V&A until May 2023

To read more about Sokari and her works, visit her website.

To immerse yourself in Carnival heritage, visit Notting Hill from 27-29 August 2022.

Next page