Driver safety training achievements

Joseph Ash becomes an approved Driver CPC centre

At Joseph Ash Galvanizing, we strive to ensure our employees drive safely and efficiently when collecting and delivering projects to our customers. As part of this process, we provide a fleet of modern and reliable trucks and regular driver training.

Our training efforts have recently received a boost at Joseph Ash because Simon Keane – Group H&S Transport Manager – has successfully gained DCPC training centre approval from JAUPT, this allows him to train other drivers and write approved driver safety course materials. In addition, classes will be delivered to other colleagues across our plants, helping them increase their driver safety and vocational training.

Simon’s first course is titled ‘Load Build and Load Restraint Principles’. He also plans to write more classes based around:

- Driver safety

- Customer service

- Health and wellbeing

- Company policies and practices

As Simon has become an approved trainer, it means the following Joseph Ash sites are now classed as Driver CPC Training Centres:

- Bilston

- Telford

- Medway

- Walsall

- Chesterfield

- Hull

Simon aims to deliver training at all sites and invite Joseph Ash/Premier Galvanizing drivers from other sites.

Congratulations to Simon for achieving the approved status for himself and the Joseph Ash Group. This is an excellent job well done and proof that Joseph Ash continually looks after its employees and invests in its people.

Next page

Over 40 years ago, Netherton Colts FC started in the Midlands. Since then, the Club has given sporting opportunities to hundreds of local children and has positively impacted the local community. The Club currently has 13 teams across all age groups from under 7 through to open age 18+. It also runs the Netherton Colts Soccer Clinic, an open ability training scheme for boys and girls ages 4-8, introducing them to football.

This season the U7s team are playing in the Stourbridge and District Youth Football League under the Birmingham County Football Association, and Joseph Ash Galvanizing is a proud sponsor.

Matt Cooper, Netherton Colts U7s Coach told us: “The U7s team has developed a fantastic hardworking attitude and desire to improve over pre-season, and they are now seeing the rewards for their hard work. They have had a tremendous start to the season, and they are playing with so much enjoyment and getting brilliant results. This year they’ll also look great as the sponsorship money from Joseph Ash has enabled us to provide team training wear and training equipment.

“We are aware of the potential impact we can have on the young players’ lives. We hope to develop the youngsters not only as football players but also to help build their confidence, respect for people and the world around them, and play a part in having a positive impact on our communities in the future.”

Good luck for the 2021/2 season Netherton Colts U7s!

CEO Steven Hopkins visits the ancestral home of the Joseph Ash family.

Last weekend our CEO Steven Hopkins had the pleasure of visiting Packwood House in Warwickshire. The National Trust owns the house and if you like visiting heritage properties, this is well worth a trip, not only to see an example of 16th-century architecture but also to walk around the renowned gardens, with their herbaceous borders and a fine collection of yews.

But why is this of particular interest to Joseph Ash Galvanizing?

Packwood was first built around 1570 by the Fetherston family. However, by the early 1900s, it became home to Alfred Freer Ash, the son of Joseph Ash (1824-1915) – who had founded Joseph Ash Galvanizing in 1857. Alfred Ash died in 1921 and bequeathed his estate to his son, Graham Baron Ash (1889-1980), who set about restoring and extending it between the First and Second World Wars.

He filled it with fittings and furniture throughout these years, which he rescued from old, demolished houses, resulting in a place described as ‘Jacobean meets Edwardian’. There are some very fine examples of early English furniture and tapestries to be seen there.

Graham Baron Ash once said: “I am rescuing whatever I can from other places and preserving it here. I do this as an antidote to the decay and demolition of so many old houses all over the country.”

This thought-process gladdens us. To this day, Joseph Ash Galvanizing places great importance on sustainability and the benefits of ‘Making-Using-Reusing-Remaking-Recycling’, so it’s wonderful to see this ethos wholeheartedly embraced by the original family behind the Company.

If you’d like to visit Packwood House, find out more at the National Trust.

See a photo of Joseph, Alfred and Graham Baron Ash at Packwood House in 1905.

Next page

We’re celebrating after landing the internationally-recognised RoSPA Award for the eighth year in a row!

Joseph Ash Galvanizing has received a RoSPA Gold Health and Safety Award for working hard to ensure our staff, customers, clients, and contractors get home safely to their families at the end of every working day.

Organisations receiving a RoSPA Award are recognised as being world-leaders in health and safety practice. Every year, nearly 2,000 entrants vie to achieve the highest possible accolade in what is the UK’s longest-running H&S industry awards.

Mick Jackson from Joseph Ash Galvanizing said: “It’s great that we have won the RoSPA Gold Award. This is the eighth consecutive year we have been recognised for our excellent health and safety standards, performance and systems, and it gives us immense pride.”

Julia Small, RoSPA’s achievements director, said: “The RoSPA Awards scheme is the longest-running of its kind in the UK, but it receives entries from organisations across the globe, making it one of the most sought-after achievement awards for health and safety worldwide.

“RoSPA is very proud of the achievements of its entrants, and with this award we recognise the best of the best, those organisations that have gone the extra mile, raising the bar for the delivery of safety in the workplace. Employees, wherever they may be, should be able to go to work safe in the knowledge that they will return home unharmed and healthy at the end of every day. Our RoSPA Award winners are central to achieving this goal. By entering they are driving up standards and setting new safety benchmarks for organisations across the world. Currently, around 7million people are directly impacted by the RoSPA Awards, but the scheme’s global influence is even wider – with nearly 2000 organisations from 46 countries represented this year. I would also particularly want to thank our main sponsor NEBOSH, the National Examination Board in Occupational Safety and Health – for their continued support for the 16th consecutive year.”

For more information about the RoSPA Awards visit www.rospa.com/awards

Next page

We’re looking for additional hot dip galvanizing operatives for our Bilston, Bridgend, Chesterfield, Corby, Hull, Medway, Telford and Walsall plants. Are you interested?

We’re searching for reliable, flexible, self-motivated and hardworking individuals, to be employed on a full-time basis (after successful completion of a probationary period).

The plants operate 24 hours with team members working on a rotating shift system (including some weekends) to meet customer demand.

The role ensures the safe and efficient processing of work, from receipt through to the galvanizing process to finished product ready for despatch.

We offer a structured training programme for all team members.

Applicants must be physically fit and work well in a team within a fast moving production environment, where excellent customer service and high product quality is the key to our continued success. An excellent attitude towards health and safety is a pre-requisite of the role.

For further information please email:

Rob Nelson (Divisional Manager at Joseph Ash Bilston)

Kevin Williams (Divisional Manager at Joseph Ash Bridgend)

Mark Payne (Divisional Manager at Joseph Ash Chesterfield)

David Prattis (Divisional Manager at Premier Galvanizing Corby)

Alex Camp (General Manager at Premier Galvanizing Hull)

Tim Palmer (General Manager at Joseph Ash Medway) or Joel Fletcher

Stuart Cobourne (Divisional Manager Joseph Ash Telford)

Charlie Singh (Divisional Manager at Joseph Ash Walsall)

Discretion assured. No agencies please.

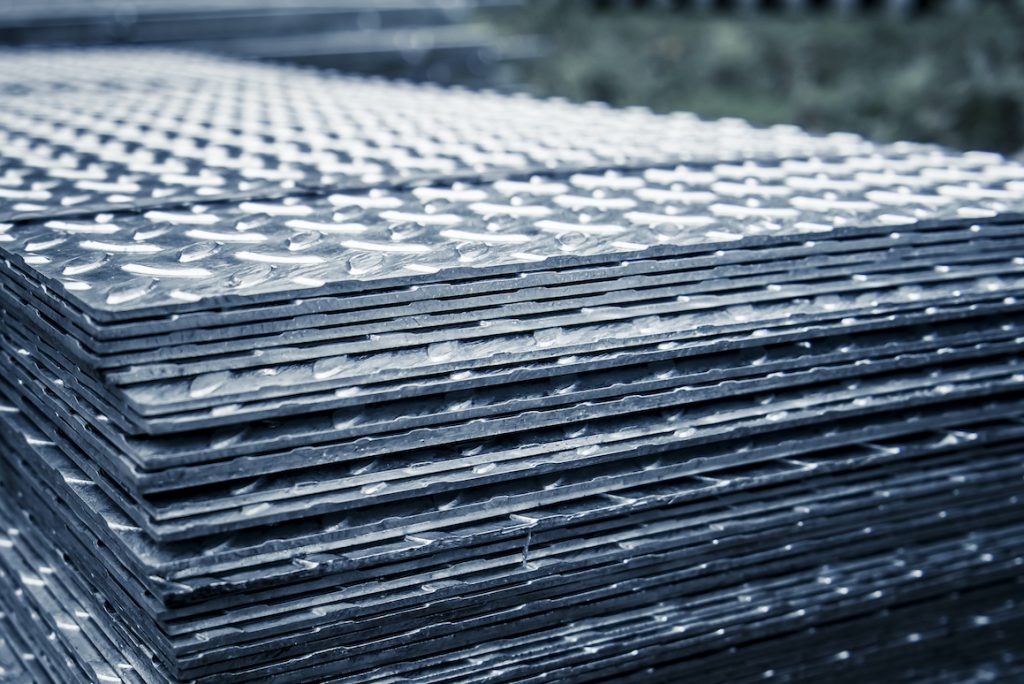

Next pageGalvanized steel is an integral part of everyday life and is all around us. But how does its prevalence today affect the environment of the future? How sustainable is it? What role does it play in the circular economy? And is the galvanizing process itself environmentally friendly?

Steel is essential for housing, infrastructure, transport, manufacturing, and agriculture. Used as frames for our buildings, safety on our roads, and support for the bridges we cross, we must never waste the resources used to produce it by throwing it away when the original function is no longer valid. Instead, we must repurpose steel, especially if the world wants to move away from traditional business models of use-throw-away-remake to a more environmentally friendly, sustainable circular economy that aims to eliminate waste and repurpose resources.

What is a circular economy, and how can galvanizing play a part?

A circular economy encourages materials to be made, used, reused, remade, and recycled.

Hot dip galvanizing fits perfectly into a circular economy because it optimises the durability of steel (enabling it to be used again) and facilitates the ease of reuse. It can be recycled if there’s no immediate need to repurpose it. Here’s how:

Optimising durability

When steel is galvanized, it is immersed in a bath of molten zinc, where it alloys with the iron in the steel to form zinc/iron alloy layers. These layers form the basis of the coating, which is covered with free zinc as the steel lifts from the galvanizing bath. The result is a robust, durable, corrosion-protective finish that will last many years.

Without a galvanized coating, steel corrodes rapidly, leading to a short lifespan. However, with a galvanized coating, steel can last for decades before the base steel is exposed, giving long term protection. This means that steel can be used for the original purpose for which it was fabricated, and – once the project is dismantled – the steel is still good enough to be used elsewhere.

Facilitating ease of reuse

Once a structure – such as a house or fencing – reaches its end of life, the steel can easily be repurposed if it has been hot dip galvanized. The galvanized coating protects the steel from impact and abrasion when disassembled and reassembled.

Recycling

Finally, hot dip galvanized steel fits nicely into a circular economy because it can be melted and used repeatedly without losing quality if there is no immediate need for repurposing.

The zinc coating can also be reused. Zinc and steel are recycled in well-established steel recycling processes. The zinc particulates are returned, without loss of properties, to zinc production plants, where they are incorporated into zinc ingots and reused in the galvanizing process.

How else does the galvanizing process enhance sustainability?

A hot dip galvanized finish gives steel a long life and durability. In addition, it creates a maintenance-free finish, which lessens the carbon emissions usually associated with the upkeep of non-galvanized steel.

Mick Jackson from Joseph Ash Galvanizing says: “Imagine a bridge made from non-galvanized steel. It would need maintenance every year to protect it from rust and corrosion. It would also need repainting at regular intervals. This requires paint, a workforce, transport for the workers and a means to protect the land or water below from paint contamination. This maintenance is not required if the same bridge is made from galvanized steel, therefore carbon emissions are greatly lessened.”

Is the galvanizing process environmentally friendly?

Galvanizing plants are self-contained, with steel going in at one end and the final product coming out at the other.

Modern galvanizing plants also use zinc very efficiently throughout the galvanizing process. For example, excess metal from the dipping process deposits back into the galvanizing bath. Zinc that oxidises on the surface is removed as ash and recycled, and dross from the bottom of the bath is routinely removed and has a high recycling value.

Other process consumables, such as hydrochloric acid and flux solutions, have important recycling or regeneration routes. Spent hydrochloric acid solutions are used to produce iron chloride for treating municipal wastewater, for example. Closed-loop flux recycling is also used in many plants, and improved monitoring and maintenance of flux tanks reduce the volume of solids for disposal. Compared to other coating technologies galvanizing uses low volumes of water, with plants rarely discharging wastewater. Any wastewater generated can be treated and reused, with only small volumes of stable solids requiring external disposal.

While not considered a particularly energy-intensive sector, the galvanizing industry also has set targets for energy efficiency and improved energy management. New technology has seen improvements in burner efficiency, bath lid efficiency, and reuse of waste heat to warm pre-treatment tanks. Plant emissions are also carefully controlled to ensure neighbouring communities are not adversely affected.

A strong commitment to the circular economy

The Managing Director at Joseph Ash Galvanizing, said: “We count ourselves fortunate to be involved with such a sustainable product, playing, as it does, a critical role in extending the life of steel structures by decades. In addition, reducing our environmental impact has been close to our hearts for many years, hence our heavy investment in fume capture and recycling by-products.”

We firmly believe in a circular economy, where the needs of present-day society are met, without compromising the ability of future generations to meet their needs.”

Get in touch to find out more about hot dip galvanized steel or the sustainability processes at Joseph Ash.

You can view the new EGGA guide – ‘Galvanized Steel and Sustainable Construction: Solutions for a Circular Economy’ here.

Next page

As Spring has sprung and it feels like a newly invigorated year, we’re pleased to announce the delivery of some new trucks at Joseph Ash Medway.

The new trucks arrived recently, and they have been part of a transport overhaul initiative by Rob Haynes, the Transport Manager at our Kent plant.

Since Rob joined Joseph Ash Medway three years ago, he has streamlined the fleet of lorries from 16 11 x 18ton Rigid’s, 1 x 7.5ton and four Artics) down to 12, (8 x 18 tonne Rigid and four x Artics). The purpose of the streamlining was to utilise all available space on each vehicle rather than running ‘half empty’ vehicles, maximising the number of deliveries and collections each vehicle can achieve, without compromising service.

Safety has also been a key goal for Rob. In November 2019 the plant received four new Mercedes Benz Actros tractor units, with the latest mirror cam technology and additional safety features, including intelligent breaking systems and lane control. The dash and driver controls are all touch screen for ease of use and hi-spec CCTV was fitted. Left turn and reverse audible warning systems were also added, and Rob is currently looking to add live cameras to view the rear of the vehicles.

In February 2021 Medway received the first of their new Mercedes Benz Antos rigid vehicles, to replace the 2016 fleet. These have the same specification, including the same safety features fitted, as the new tractor units.

Between now and April the plant will also be replacing two more of the Rigids. A further three will be replaced in November.

Finally, not only is health and safety important for our drivers, but ease of use. To this end Rob re-designed the rear of the trucks with lighter side doors, more durable hinges and catches, stronger posts and access doors either side, with drop down steps and grab rails.

He is currently in talks with Herrings Trailers, to replace Medway’s existing trailers, due for renewal in November 2021. These will be built to the same specification as the rear of the rigid vehicles.

For more information about the transport initiatives at Medway, please get in touch with Rob Haynes on Mob: 07734 875249 or Email: robh@josephash.co.uk. You can also email: transport@medgalv.co.uk.

Next page

In December 2020 (including throughout the Christmas period), the Joseph Ash Chesterfield plant underwent a series of major improvements that has helped the plant to get off to a flying start in 2021. The following works took place which will provide huge improvements to Joseph Ash employees and customers alike:

- The 40 year old concrete in the road at the main gate was replaced, making the surface smoother for visitors

- A new entrance and exit gate was installed to improve traffic flow around the site

- We also installed two new overhead cranes

- We carried out a series of total preventative maintenance projects to keep the site running smoothly and efficiently

- Finally, the whole of the inside of the plant was repainted, making it clean and fresh for the New Year!

If you’re a regular customer of our Chesterfield plant, we hope you find these improvements beneficial to the services we provide to you. Do let us know if you have any feedback, or you think there are any other improvements we could make that could make your lives easier when you visit the plant.

Next pageWe’re pleased to announce FORS renewal for Joseph Ash Medway, having once again met the bronze level requirements of the Fleet Operator Recognition Scheme (FORS).

The Fleet Operator Recognition Scheme (FORS) is a voluntary scheme that covers all aspects of vehicle emissions, fuel efficiency, economical operations and safety.

FORS enables vehicle operators to know they are helping to increase efficiency, win work, and reduce costs. It also provides peace of mind to vehicle operators that legislative requirements are being met. Finally, it enables operators to know they are becoming safer and greener.

Joseph Ash Galvanizing Medway was first awarded the bronze certificate for FORS in 2016.

Thank you to FORS for assessing us. Thank you also to the team at Medway who worked hard to receive the award.

Next pageEnd of year message from Steven Hopkins, MD, Joseph Ash Group

Dear Customers,

It’s the end of the year… Where did 2020 go to? It seems to have been non-stop, with a huge amount more to think about and manage than normal.

As you might know, in the Joseph Ash Group we made the decision early in the Pandemic not to allow the situation to impact our customers, but nor could we allow our employees to be put at risk. So we worked hard as one big team across all eight plants to quickly develop our protection systems and order extra sanitising gels and PPE as quickly as possible. The Furlough Scheme allowed us to reduce concentrations of staff (although we’re pleased to say we are able to repay it in line with the decision of our parent group, Hill & Smith Holdings PLC). Alterations to shift start and finish times helped as well.

What pleased us the most, however, were the messages of support from several customers who also stayed open and who said they would have been in difficulty without their “last production process partner”. We were also delighted to have the opportunity to showcase our abilities to many new customers who knocked on our door for the first time during the Spring lock-down, and have elected to keep us as their production partners ever since.

It also pleased us to be able to help the national pandemic effort by processing steel for much-needed facilities such as the NHS Nightingale Hospitals, an extension to an oxygen tank facility at St. Thomas’s Hospital in London, and equipment such as clinical waste bins and trucks, and crash trolleys.

I guess it should be no surprise to anyone if I say that April and May were tough months. However, we seemed to regain some equilibrium by the last week of May and volumes thereafter increased each week by several percentage points, until today we find ourselves extremely busy. This is in no small part due to our excellent Sales teams who were not furloughed and spent their time working very hard and effectively from their kitchen tables – with no office conversations about football or TV to distract them!

We have had two significant challenges to deal with in 2020 – I guess no different to many of you:

- As we “employ” around 70 agency workers in our group, mostly on a temp-to-perm basis, they were inevitably furloughed by their agency employers and many became lost to us;

- Whilst the incidence of Covid diagnoses in the Joseph Ash Group has been well below the national average (I have probably driven our people mad with constant nagging about hand-washing!), we have still temporarily lost the services of dozens, isolating due to family members testing positive. I have also been surprised how many partners of our employees are facing danger every day in the NHS and Care sectors – God Bless them all.

So, maintaining capacity has been a challenge at times, but we have been saved by the reasonable distances between our plants and a very cooperative desire by them to help their sisters. Now, we are well on the way to rebuilding our teams, with the last tranche (or recruits) set to join us in the New Year.

In all, whilst 2020 has been grim in many respects, it has given the people of the Joseph Ash Group the chance to really show their mettle and I am inordinately proud of every one of them. I believe that, whilst our profits might be down, in more ways than one this has been the finest year of our 150-year history.

But none of the above would have been possible without you, our excellent customers. You too have faced adversity, come through it and supported us in our endeavours to keep going and maintain our standards of service. What a great partnership! I thank you most sincerely for your efforts and our relationship.

On behalf of everybody at Joseph Ash, I wish you and your loved ones a happy, peaceful and healthy Christmas, and a far better New Year!

Kindest regards,

Steven Hopkins

Managing Director

Joseph Ash Group