Secure your security fencing with hot dip galvanizing

Your security fencing is the main barrier for your company or property, so you don’t want to compromise on its quality. Improving the durability and strength of your metal fences with hot dip galvanizing ensures your property remains safe and retains its visual appeal.

Timber or metal fencing?

While larger-scale companies already implement high-end steel fences, smaller-scale companies are more likely to feel content with timber fencing. While initial costs may be cheaper for timber fencing, you compromise on durability and security. Steel fencing is cheaper in the long term as it won’t need replacing as frequently. Steel fencing is also safer for your property as it is less likely to be damaged by vandals or wear down from the environment.

Benefits of galvanizing steel fencing

You may believe that steel fencing doesn’t need additional care once it has been set up. Although steel is more durable than timber, raw steel fencing is vulnerable to corrosion. Therefore, a steel coating method such as hot dip galvanizing protects your steel fencing and improves its durability.

- Corrosion Resistance: Railings and fences are exposed to the elements, such as heavy rain. Galvanizing provides a durable and long-lasting coating that protects the metal from the corrosive effects of rust, increasing the steel fencing lifespan.

- Low Maintenance: Galvanized railings and fences require minimal maintenance compared to their ungalvanized counterparts. The galvanized coating provides a protective layer that only needs cleaning occasionally to keep it looking as good as new. This saves you time and money on future maintenance treatments. You also maintain your company image as your fencing won’t visually be seen as in a permanent state of poor condition.

- Cost-Effective: The upfront cost of galvanizing is offset by the long-term savings in maintenance and replacement costs.

- Sustainability: Galvanizing is an environmentally sustainable choice. The zinc coating used in galvanizing is 100% recyclable, making it an eco-friendly option for the industry. Joseph Ash Galvanizing cares about the environment and ensures the galvanizing process fits into a circular economy.

Painting galvanized fences

A lot of fencing companies paint their metal fences to provide a surface-level protection. Paint also adds a splash of colour to fences, increasing their visual appeal. However, paint is not an ideal coating choice to use on metal.

While it’s possible to paint over galvanized metal, powder coating has numerous benefits compared to paint. Powder coating and paint are very similar surface coating methods, but powder coating ensures your metal fences are more durable and cost-effective. When galvanizing and powder coating are used on the same steel fence, this is known as a duplex coating. We’ve listed some of the benefits of duplex coatings here.

Joseph Ash Galvanizing has over 160 years of hot dip galvanizing expertise. We have numerous case studies from customers in the fence, gate and railings companies. Joseph Ash Medway is also the proud developer of the Mono Hinge range of safety gates – the perfect safety gate to accompany small-scale fencing.

Find your nearest branch today, or request a call-back.

Next pageStructural steel is used in the construction industry for load-bearing structures. Its high strength-to-weight ratio supports heavy loads such as bridges, transport systems and buildings. However, issues arise when structural steel can no longer do its job effectively.

Corroded steel is dangerous

Corrosion can threaten the load-bearing capabilities of structural steel. If decay occurs, the structural integrity of the steel weakens, which is potentially very dangerous. The heavy steel structure could collapse – not only ruining your fabrication, but also cause harm or even death.

Corrosion happens when steel is exposed to moisture, air, and other environmental factors. It can appear in a matter of days if there is no coating to protect the steel. Fortunately, galvanizing is a trusted method of protecting steel against corrosion.

How does galvanizing protect structural steel?

During the galvanizing process, steel is dipped into a bath of molten zinc. When the steel lifts from the bath, it is coated with a layer of zinc that has metallurgically bonded to the steel. This provides a long-lasting and durable barrier against corrosion.

The zinc coat also protects the steel against scratches and damage that could happen during storage and transportation.

Reasons to galvanize structural steel

Ensuring your structural steel fabrication is protected against corrosion is vital so that load-bearing structures do not collapse.

Galvanized steel remains strong for 35 – 100 years (depending on the environment), withstanding harsh and unpredictable weather conditions. Imagine how important this is for a bridge that may have cost millions and taken years to build.

Hot dip galvanizing also ensures that structural steel does not need regular maintenance, which could be the case with other coating systems. As a result, you save both time on money on arranging recurring steel maintenance (or as a worst-case scenario, re-making the fabrication from scratch).

We’ve compiled a list of some of the best reasons to galvanize your steel.

Environmental impact of galvanizing structural steel

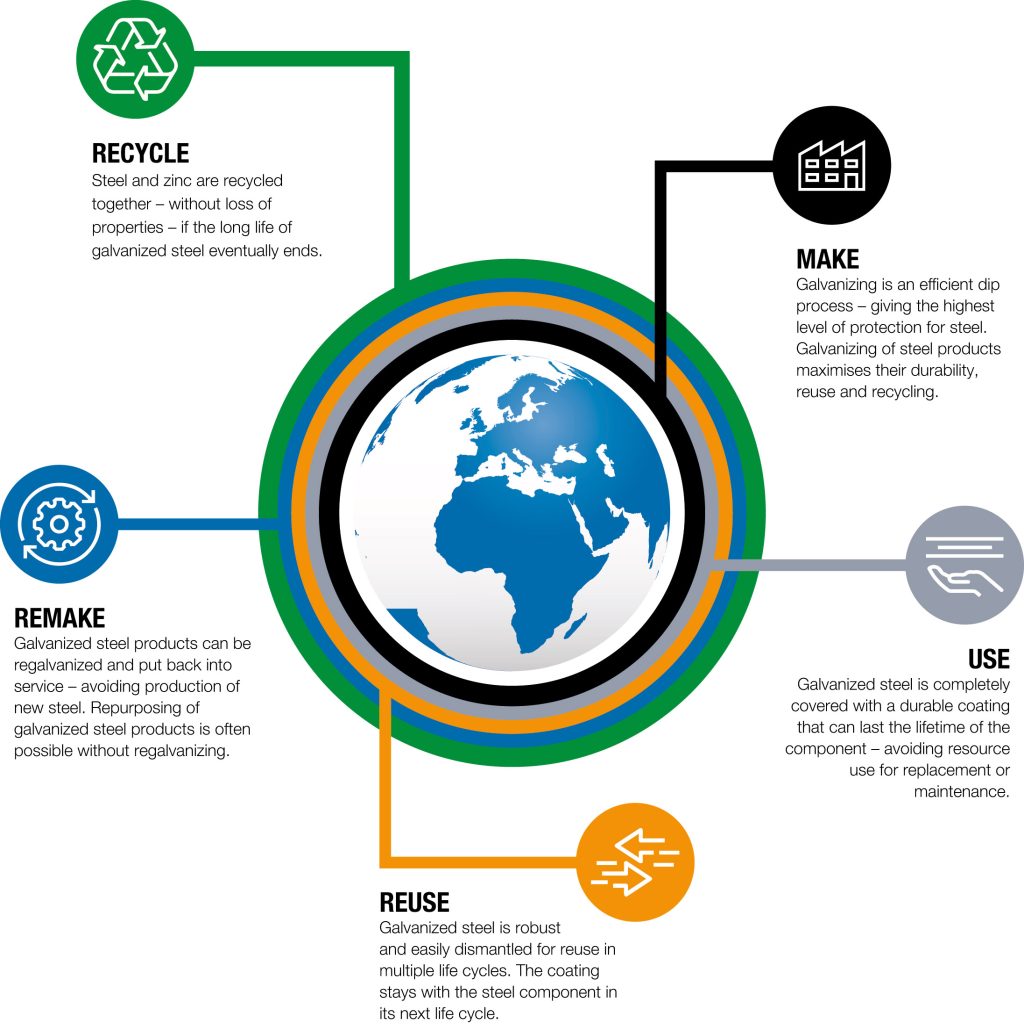

As a material, galvanized steel is sustainable and environmentally friendly. It also plays a role in the circular economy, readily facilitating the principles of make, use, remake, reuse and recycle.

The galvanizing process itself is environmentally friendly, too. At Joseph Ash Galvanizing, we take a proactive approach to controlling emissions and ensuring the highest environmental protection for every project or function of our operations.

Structural steel galvanizing

With nine UK sites, we are never too far away to protect your steel.

- We’ll collect and deliver your steel to our site ✔️

- Comprehensive technical support, guidance and assistance at every stage ✔️

- Hot dip galvanized to BS EN ISO 1461 standards ✔️