Lily Mae Foundation Charity Golf Day

Thank you to everyone who joined us!

The annual Lily Mae Foundation Charity Golf Day and Dinner Dance took place on Friday 14 April. It was a great day! Thank you to everyone who joined us.

The Lily Mae Foundation supports parents and families after a stillbirth, neonatal death, miscarriage or medical termination. We’ve supported the charity for over a decade, regularly attending its annual golf/dinner dance event and helping to raise in excess of £150k.

There were 32 teams who took part this year, made up of clients, suppliers, and team members across our Joseph Ash Galvanizing, Premier Galvanizing and Widnes Galvanising plants.

Attendees were greeted with a charity gift bag containing goodies and snacks for the day. They then fuelled up with bacon baps and coffee before teeing off. Teams concluded the day with the evening dinner dance, where we witnessed fewer bogeys, and a lot more boogie!

Congratulations Lily Mae Foundation on another fabulous event!

An amazing initiative by Joseph Ash Walsall funds for a local food bank just in time for Easter

What a fantastic day at Joseph Ash Walsall! We recently set ourselves the target of donating Easter Eggs and funds to help support Breaking Bread, a much-needed food bank based in Wednesbury in the Midlands.

Breaking Bread is a non-profit community interest group that runs solely off donations from the public. It has been running for 10 years and, in that time, has gone from servicing 38 families to 200 families a month.

When we started the initiative, our initial target was £1000 and gathering enough Easter Eggs to give to all the children of families who visit the food bank.

But through the kind donations of all our team, clients and suppliers, as well as donations and support from our other plants in the Joseph Ash Group, we managed to raise an enormous £3900 and enough Easter Eggs for everyone who visits the food bank (children and adults alike).

Amy Leachman and Zoe Chapman from Joseph Ash Walsall delivered two carloads of Easter Eggs to the charity earlier this week, and today we invited Lyn Walford and Joyce Turner from Breaking Bread to visit our plant, enjoy some lunch, and attend a presentation to receive the remaining egg donations and the cheque to help fund future food purchases.

Lyn Walford said: “We run Breaking Bread food bank as a non-profit. We’re all volunteers. We do it to support the local community. People come to us. They’re generally in a distressed state. They’re desperate for help. Some may not have eaten for several days, so we provide them with food to last them over three to four days, and if they’re not sorted after that, they can come back again, and we will help them further. What you’ve done here… it’s amazing. The support you’ve given us – and ongoing support, as we’ve discussed today – is fabulous. And it’s also meant that where we can normally only give little children Easter Eggs, today we’ve been able to give everyone Easter Eggs! The funds of almost £4000 will help us stock up on food for local families. Thank you!”

Like many food banks, the charity finds it more challenging to provide a service due to the growing demand and lack of donations due to the current cost of living crisis. However, we’ve been delighted to help.

The Just Giving page for this initiative is here if you’d like to contribute further to the charity.

Have a great Easter and Bank Holiday weekend, everyone!

Welcome to our March 2023 newsletter.

This month we’re discussing hot dip galvanizing for structural steel, the RIDBA Awards 2023, a 45th anniversary for Dalit Singh, and ‘Know your microns’ from the Galvanizers Association.

We’re also shining a light on our Bilston plant, plus a new member of our team at Widnes. Plus we invite you to support our Easter Food Bank Drive to help the Breaking Bread Food Bank charity.

To read a copy click here.

To receive a copy of the newsletter in your inbox each month please subscribe.

Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

The Joseph Ash Group has nine plants across the UK, from Medway in the South to Hull in the North. We’re putting the spotlight on our Bilston to share its history and capabilities.

About Joseph Ash Bilston

Joseph Ash Bilston is located on Springvale Park, where esteemed business Bilston Steelworks was developed in the 1700s, making steel for over 200 years.

Joseph Ash Bilston is home to the productive semi-automatic facility in the UK. It also opened its energy-efficient office block in 2022.

Finally, the team at the plant has been working hard on environmental initiatives for several years, installing equipment such as solar panels, solar storage systems, an air source heat pump, radiant ceiling grid panels, and 60 double-glazed windows using the latest energy efficient glass.

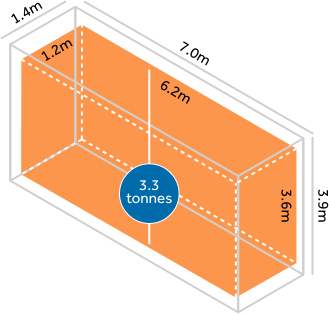

UK’s deepest galvanizing bath

Joseph Ash Bilston is home to the deepest galvanizing bath in the UK, with a total depth of 3.9m and a dipping capacity of 3.6m. These dimensions help make it the ideal place to dip long fabrications such as motorway guardrails, fencing products and industrial flooring.

With its collection and delivery service, the plant services clients from areas including Warwickshire, Worcestershire, West Midlands, Gloucestershire, Oxfordshire, Northamptonshire, Leicestershire, Staffordshire, Shropshire, and Herefordshire. Work can also be transported work to other Joseph Ash plants using our own fleet of trucks.

More than galvanizing

As well as galvanizing, Joseph Ash Bilston can provide shot blasting (through an external shot-blasting subcontractor). Bilston can also offer powder coating, duplex coatings, and spin galvanizing via the other Joseph Ash Galvanizing plants.

We also offer a range of additional services:

- Collection and delivery: We can collect and deliver your steel to and from our site, saving you time.

- Full technical support: Ensures customers receive guidance and assistance at every stage, guaranteeing a smooth galvanizing process.

- Packing and bundling: We can bundle, pack, and label your steel per your requirements and can accommodate if you need items delivered to the end user or prepared for export or containerisation.

Extended opening hours and quick turnaround times

Joseph Ash Bilston has extended opening hours to assist customers wishing to drop work off early and collect it late. Get in touch with us to find out more.

We can also provide a quick turnaround (overnight and within 24 hours) by prior arrangement.

Quality and accreditations

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our hot dip galvanizing is to BS EN ISO 1461 specifications. These standards help ensure a consistent, reliable coating is achieved from the process, with guidance on minimum specifications for coating thickness. We also hold the NQA ISO 9001:2015 accreditation for Quality Management Systems, ISO 14001:2015 for Environmental Management Systems, and ISO 45001 for Occupational Health and Safety Management Systems.

Whatever your requirements, at Joseph Ash Galvanizing are here to help. Contact our Bilston team today for more information.

As the UK is experiencing high levels of inflation and energy and food price hikes, low-income families have been hit the hardest and more people are turning to food banks for help.

With Easter fast approaching, most of us look forward to our chocolate fix. However, many families can’t afford the food they need, let alone the luxury of a chocolate egg.

With this in mind, Charlie Singh (Divisional Manager) and his team at Joseph Ash Walsall are trying to raise as much money as possible to support Breaking Bread, a food bank in the Midlands by providing them with Easter Eggs and other food products to ensure many more families can enjoy the things most of us take for granted over the Easter period.

Please help us make a real difference by visiting the Just Giving page and donating. No matter how small, any amount will be appreciated, and you can donate anonymously (if you prefer).

Further information is on the Just Giving page.

Alternatively, it is quick and easy to donate simply by scanning the QR code.

Submit your entries by 31 March

The RIDBA Building Awards is taking place again in 2023, and the deadline to submit your entries is 31 March 2023. If you have a building project you’re proud of and would like to enter, submit your entries by the deadline for your chance to win.

There are several categories to enter, including

Industrial and Production Awards

The RIDBA Building Awards ceremony will take place in Cambridge on 22 September 2023 and Joseph Ash Galvanizing is proud to be a Premium Sponsor.

The photo above is the Wharton Cattle Shed in Lincolnshire by S&A Fabrications, winner of the Livestock Award.

The photo below is Lingwood House, the RIDBA Overall Winner of 2021, constructed by M D Anthony Ltd.

Will your project be a winner?

Visit the RIDBA website for further details.

Welcome to our monthly newsletter! This month we’re celebrating a night-time hike for charity and galvanized letters at Evenley Wood Garden. We meet Matthew Phillips during National Apprenticeship Week. And we’re sharing the love for 40 year’s service at Joseph Ash. (Anniversary date: Valentine’s Day!)

We’re also pleased to have launched two new websites for Widnes Galvanising and the popular Mono Hinge Gates. Further details are below.

To read a copy click here.

To receive a copy of the newsletter in your inbox each month please subscribe.

Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

Evenley Wood Garden (EWG) – located in Northamptonshire – is a beautiful 60-acre woodland garden open to visitors. As well as being able to see plants, unusual trees and shrubs, visitors can also take part in wine-tasting events, plant fairs, craft days, and a host of other fun activities. It’s a lovely day out!

To greet visitors to the park, the team at Evenley had a great idea: placing three giant steel letters – EWG – at the entrance that people would see and engage with as they approach.

Alison O’Hare, Marketing & Events Co-ordinator at Evenley, contacted a local blacksmith company, Baillie & Co, for help.

Adam Baillie from Baillie & Co is a self-employed blacksmith, fabricator, welder, and metalworker. As his studio is just down the road from Evenley Wood Garden, and he often takes part in events there, he relished the opportunity to produce the letter installation.

Adam designed and fabricated each letter to not only be freestanding letters but also planters that can be decorated with stunning floral displays by the gardeners at Evenley.

The letters are solid steel (apart from the hollow base). They are 1.5m high – perfect for visitors to the park to interact with and have their photos taken beside.

Because the letters are steel, they need galvanizing for protection against rust and corrosion.

Adam booked the galvanizing service with Joseph Ash Walsall, where he received excellent service.

Adam was concerned about the letters during the galvanizing process and the potential damage caused by how the letters would have to hang over the zinc bath. However, his concerns disappeared after speaking to Paul Hudson at Joseph Ash Walsall.

Paul happily took the time to explain the importance of vent holes and describe the hanging process.

During these calls, Paul also arranged the collection and delivery of the letters to save Adam from having to manage these logistics separately.

Adam was very pleased with the galvanized finish for the letters. Before delivering them to Evenley Wood Garden, he also applied a final light wash to create a burnished effect.

Adam chose a wash instead of paint to make the letters more environmentally friendly.

The letters are now at Evenley Wood Garden, looking amazing. Adam is looking forward to seeing how the Garden’s visitors react to them. So are we!

_____________________________________________________________________________

About Adam Baillie and Baillie & Co

Adam is a highly experienced metalworker and award-winning blacksmith, with a passion for contemporary design. He thrives in commercial workshops producing superior standards of creative craftsmanship, whilst offering the best in customer and client satisfaction. He provides the following services: bespoke design, conservation and restoration, and general metalworking.

Contact Adam at contact@baillieandco.co.uk for any metalwork needs.

_____________________

Venting hints and tips

For hints and tips on the best way to prepare steel for fabrication, download our free Safe Design for Hot Dip Galvanizing poster.

Welcome to our monthly newsletter – the January 2023 edition.

This month it’s all about newness! Our new Commercial Manager at Widnes, new inventions, new industry events/dates to remember for 2023, a new set of values, a new kettle at Hull, plus how about a ‘new year, new job’?

Finally, the entry deadline for this year’s Structural Steel Design Awards is just around the corner. Is your application ready? Further details are in the newsletter.

To read a copy click here.

To receive a copy of the newsletter in your inbox each month please subscribe.

Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

We’re pleased to announce the recent installation of a new galvanizing kettle at our Premier Galvanizing Hull plant.

It’s quite a logistical exercise to remove an existing kettle and replace it with a new one. Commissioning and planning the changeover takes months. And the installation – including removing/recycling existing zinc, dismantling the bath, fitting a new bath, and adding new zinc ingots – takes a whole week. The bath also had to be transported from Germany first!

The bath dimensions are the same as before: 7m length x 1.2m wide x 3.2m deep. However, it has a thicker wall than previously (now 60mm instead of 50mm).

For health and safety reasons, it’s typical to change galvanizing baths every 7-10 years as the wall thickness degrades over time, specifically in areas with a temperature difference, such as the ‘wash line’ and above the Dross protection. Structural integrity is crucial for health and safety, so even though we still had a few years left in our previous bath, we always opt for the cautionary approach.

Thanks to W. Pilling in Germany who provide all our kettles, and the following companies who helped with the installation: Projector Lifting Service, Zinco, Westech and Thermetal Metallurgical Furnace Engineers.