RIDBA Building Awards 2023 shortlist

We are delighted to announce the shortlisted entries for this year’s RIDBA Building Awards. These awards, held every two years, celebrate excellence in rural and industrial building design and fabrication. As a premium sponsor for the event, it’s exciting to see which projects and companies are in the running to receive one of the coveted awards.

There are eight award categories in total, and the shortlist for each category is as follows:

Farm storage

- New grain store facility, LF Pearce & Son

- Replacement general purpose building, A.C. Bacon Engineering (photo from A.C. Bacon)

- Sakata UK Ltd, Timmins Engineering

- S. Batty & Son, Colley Farm Buildings

- Forestry workshop, Wareing Buildings

- Sir Richard Sutton Estates, Timmins Engineering

New product or service

- Voortman V807, Cutmaster Machines

- Halo Solar, Ash & Lacy

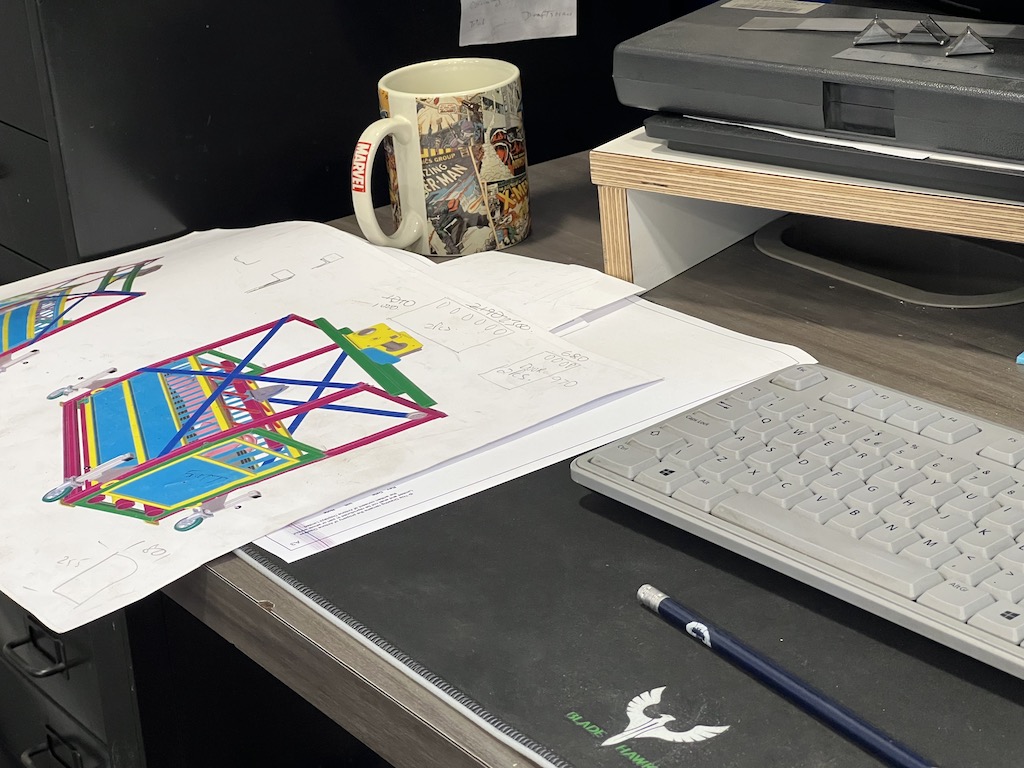

- Innovative pig lift, Designeering (photo from Designeering)

- Tekla PowerFab 2023, Trimble

- STRUMIS e-learning, STRUMIS

- Hybrid Supa Slat, Wolfenden Concrete

Commercial

- CJ Cox Limited New Workshop, Rose Engineering

- Cambridgeshire Fire & Rescue Station, A.C. Bacon Engineering

- Franks Ice Cream, Shufflebottom

- Tong Engineering, Timmins Engineering

- Roundhouse Play Area, S&A Fabrications (photo from S&A Fabrications)

- Morgan Sindall Merthyr Bus Station, Shufflebottom

Livestock

- West Midlands Safari Park, Minshall Construction (photo from Minshall Construction)

- Ash Holt Barns, Timmins Engineering

- Ben Pauling Racing, Naunton Downs, D Jones Welding

- Pembertons cattle shed, Wareing Buildings

- Oxey Farm suckler building, M D Anthony

- Sunnylands, Powell & Co Construction

Industrial and production

- Dawson’s Wharf pellet bund, S&A Fabrications

- Cropper Close, Henco International, Wareing Buildings

- Graham & Brown, Wareing Buildings

- McMurrays Haulage, Wareing Buildings

- Bacton Transport, M D Anthony

- Smart Systems, Shufflebottom (photo from Shufflebottom)

Residential and offices

- Luxury residential property in Poulton-le-Fylde, Wareing Buildings

- Island estates, Shufflebottom

- The Property Hub, M D Anthony (photo from M D Anthony)

- Luda barns, Timmins Engineering

Prizes will also be handed out for outstanding workmanship and training.

Please mark your calendars for Friday, 22 September, when we’ll gather in Cambridge to congratulate the winners and runners-up.

Prepare for an evening of sophistication, with a black-tie drink’s reception and a three-course meal. Of course, the highlight of the night will be the presentation of the coveted RIDBA awards.

Please contact RIDBA directly for ticket enquiries.

Next page

Welcome to our June 2023 newsletter. Published today!

This month we’re celebrating the sustainable benefits of Bilston, ESG Week at Joseph Ash, the art and science of spin galvanizing, a RIBA for Cake Industries, and a 40th anniversary for one of our team members.

We’re also discussing the benefits of hot dip galvanizing for trailers; we meet our Group Operations Director (Neil Kanagaratnam); and shine a light on our Corby plant.

Enjoy!

To read a copy click here.

To receive a copy in your inbox each month, please subscribe.

Simply scroll to the bottom of the page and look for the ‘Newsletter sign-up’ button.

Next pageJoseph Ash takes pride in its extensive network of UK plants, from Medway in the South to Hull in the North. This month’s newsletter highlights our Northamptonshire facility, Premier Galvanizing Corby. We’re putting a spotlight on Corby to showcase its remarkable capabilities and state-of-the-art amenities.

History of galvanizing in Corby

Premier Galvanizing Corby is in a region of England historically tied to the growth and development of steel and ironworks during the Industrial Revolution. And where there’s steel, there’s galvanizing.

Galvanizing became essential as the steel industry grew in Corby. It was particularly crucial for the construction sector, where steel structures and components were exposed to the elements. Galvanized steel offers superior durability and resistance to rust. This makes it ideal for a wide range of applications, including bridges, buildings, and infrastructure.

In recent years, Corby has experienced a resurgence in its steel industry. This has been driven by investments and the growth of new businesses. Galvanizing remains vital in the town’s steel sector, ensuring the longevity and corrosion resistance of steel products manufactured there.

Today, galvanizing companies in Corby continue to employ advanced techniques and technologies to provide high-quality galvanized steel coatings. Premier Galvanizing caters to various industries: construction, automotive, agriculture, and infrastructure.

Premier Galvanizing Corby location

Premier Galvanizing Corby is located on the Willowbrook Industrial Estate. With its extensive fleet of vehicles, it covers customers’ galvanizing needs from London, Berkshire, Buckinghamshire, Hertfordshire, Cambridgeshire, Bedfordshire, Leicestershire, Lincolnshire, Nottinghamshire and Derbyshire, as well as the Midlands.

What is galvanized at Premier Galvanizing Corby?

Whether a fabricator needs a small amount of steel galvanized for a gate or railings or 100 tonnes of steel for a new building development, Premier Galvanizing Corby can help. We pride ourselves on getting it right the first time, on time, and every time to meet the varied needs of our customers.

Bath size

The bath dipping size at Premier Galvanizing Corby is 7.5m x 1.3m x 3.0m, and the team can dip 4.8 tonnes.

Additional services

As well as core services, Premier Galvanizing Corby offers the following customer amenities:

Collection and delivery service: Wherever you are or wherever the end destination for your fabrications is, Premier Galvanizing can transport your steel. We operate a fleet of four articulated vehicles capable of carrying 22 tonnes each. Plus eight rigids which can also carry up to 10 tonnes.

Full technical support: Providing customers with comprehensive technical support, offering guidance and assistance at every stage.

Packing and bundling: We can bundle, pack, and label your steel at your request. Let us know your requirements. Especially if you want us to deliver your items to the end user or prepare them for export or containerisation. Certificates of conformity can be issued upon request, and all work is conducted following BS EN ISO 1461.

On-site storage: Premier Galvanizing Corby offers ample on-site storage capacity, allowing customers to store materials conveniently before and after galvanizing.

Shot blasting and powder coating: Through an external subcontractor.

Committed to excellence and compliance

Recognising the importance of meeting customers’ time-sensitive demands, the team at Corby fully understands the significance of strict deadlines. We have extended opening hours for drop-offs and collections to provide the best assistance. Moreover, Corby offers expedited turnaround times, including overnight and within 24 hours, through prior arrangements, ensuring prompt and efficient service.

Premier Galvanizing Corby prioritises excellence in everything it does. Including maintaining the highest occupational health and safety standards, quality management, and environmental management. Certifications include BS EN ISO 1461, ISO 45001, NQA ISO 9001, and ISO 14001.

Our people

At Corby, we have a dedicated team of individuals with a wealth of knowledge and a sincere passion for their roles. From skilled shop floor operatives to transport and truck drivers, meticulous health and safety experts to the efficient administrative team, we work collaboratively to ensure that our valued customers receive the utmost service and see us as part of their team.

Contact the team at Corby today to discuss your projects.

Next page

Welcome to our May 2023 newsletter. Published today!

This month we’re celebrating new services at Widnes Galvanising, bath size matters at Joseph Ash Telford, powder instead of paint, and a 25th anniversary for one of our team members.

We’re also discussing the benefits of designing steel correctly for galvanizing; we meet a new HQ team member (David Hull); and shine a light on our Joseph Ash Chesterfield plant.

Finally, there’s a reminder about our plant Bank Holiday arrangements.

Enjoy!

To read a copy click here.

To receive a copy in your inbox each month, please subscribe.

Simply scroll to the bottom of the page and look for the ‘Newsletter sign-up’ button.

Next pageThe Joseph Ash Group boasts nine plants spread throughout the UK, stretching from Medway in the South to Hull in the North. Here, we shine the spotlight on Chesterfield, showcasing the plant’s exceptional capabilities and facilities.

Location and history of Joseph Ash Chesterfield

The Chesterfield plant is based in Derbyshire, a region of England historically tied to the growth and development of the steel and iron industry in the 19th century.

With so much metalwork and engineering in the area, galvanizing was essential in protecting steel and iron products from rust and corrosion, extending their lifespan, and enhancing their durability.

Joseph Ash Chesterfield is the largest of all our plants. It’s situated on the Holmewood Industrial Estate, just half a mile off the M1 Junction 29, and services clients from Worksop, Leicestershire, Derbyshire, Nottinghamshire, Cheshire, Greater Manchester, South Yorkshire, West Yorkshire, North Yorkshire, Lancashire, Merseyside, Lincolnshire, Staffordshire, Warwickshire, Worcestershire, and the West Midlands.

As the Chesterfield team wants to make customers’ lives as simple as possible, it provides collections and deliveries throughout the Midlands and the North and a daily milk run service within a 50-mile radius of the plant and the M1 corridor. In addition, the plant’s unique offerings in size see them regularly undertaking projects from Southampton to Aberdeen.

Fit for Nuclear accredited

Joseph Ash Chesterfield is the only plant in the UK that is certified as Fit for Nuclear (F4N), which demonstrates a commitment to quality, safety, and compliance with nuclear industry standards. Steel components could include building supports, platforms, walkways, and structural steel.

As the nuclear industry is highly specialised and safety-critical, the galvanizing must pass rigorous evaluation and qualification processes to ensure compliance with stringent standards and regulations.

Services at Joseph Ash Chesterfield

The plant is ideally suited for the largest projects, including structural sections and lighting columns, building supports, platforms, walkways, and other general fabrication work. In addition, Chesterfield is unique in that it can galvanize a 16m – 12-tonne beam to the smallest shims weighing a few kilos each. This gives customers confidence that an entire project can be galvanized at a single plant to the highest possible standard.

Additional services

As well as core services, Joseph Ash Chesterfield offers the following customer amenities:

- Collection and delivery service: Ensuring items reach Joseph Ash and are returned to customers hassle-free. We operate a fleet of seven articulated vehicles capable of carrying 28 tonnes each, plus five rigids which can also carry up to 15 tonnes. The fleet also has 48 trailers to maintain customers’ work.

- Full technical support: Providing customers with comprehensive technical support, offering guidance and assistance at every stage.

- Passivation: A 17m tank (the largest passivation bath in the UK) ensuring optimal corrosion resistance and surface finish for galvanized products.

- On-site storage: With over 10 acres of available space, Joseph Ash Chesterfield offers ample on-site storage capacity, allowing customers to store materials conveniently before and after galvanizing.

- Trailer storage: Customers can take advantage of a designated area capable of accommodating up to 100 trailers, providing a secure space for transportation needs.

- Crane gantry area: The crane gantry area at Chesterfield features ramps and bays, enabling customers to load their containers and trailers efficiently and effortlessly under six external cranes.

- Fabrication pre-testing: Chesterfield includes a dedicated area where customers can assemble and pre-test their fabrications before taking them off-site for delivery to the end user.

- Truck driver facilities: Overnight and changing facilities are available for the comfort of truck drivers. Chesterfield also has a truck stop located directly opposite the plant.

- Forklift fleet: Chesterfield will soon be in the possession of the most up to date electric fleet of forklifts using an Opti Fleet computerised system. We have four 3.5 tonne and one 4.5 combi forklift trucks.

Bath size

The bath dipping size at Joseph Ash Chesterfield is 16.2m x 1.6m x 2.3m, and the team can dip 8 tonnes (or 16 tonnes by arrangement). Double dipping can also be undertaken (height and length).

Flexibility

The Chesterfield team understand that customers often have strict deadlines to meet. To assist, the plant has extended opening hours for drop-offs and collections. Chesterfield also offers quick turnaround times (overnight and within 24 hours) by prior arrangement.

Committed to excellence and compliance

Joseph Ash Chesterfield prioritises excellence in everything it does, including maintaining the highest standards of occupational health and safety, quality management, and environmental management. Certifications include BS EN ISO 1461, ISO 45001, NQA ISO 9001, and ISO 14001.

The Chesterfield team also understands the importance of documentation and transparency and provides Certificates of Conformity for each job whenever required.

Contact them today and let the team exceed your expectations with their expertise and commitment to service.

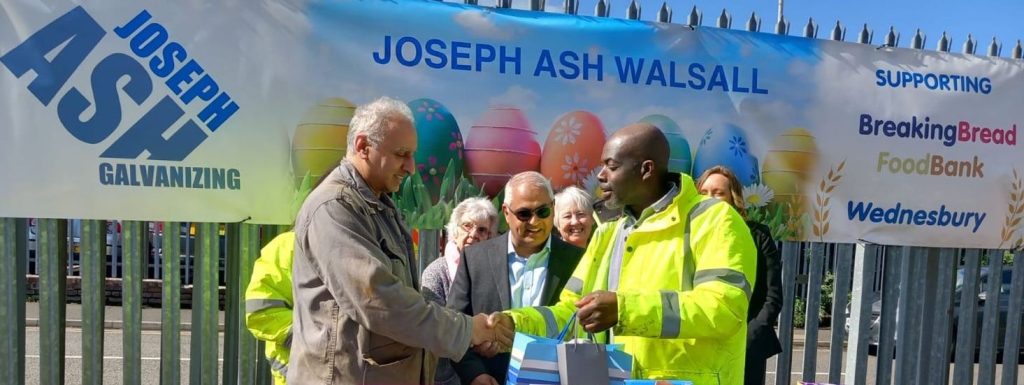

Next pageIn 1998, Ranjit Singh started work as a new team member at our Walsall plant. Fast forward 25 years, and we proudly say he is still here and part of our Joseph Ash family.

Ranjit began his career in galvanizing on the yard. After that, he worked in the fettling/packing team before moving on to other groups and departments, including as a Galvanizing Operative (his current role).

What Ranjit doesn’t know about galvanizing isn’t worth knowing as he has worked in most parts of the plant throughout his career!

During his 25 years of service at Joseph Ash, Ranjit has displayed all the attributes required to be a fantastic member of our team. He has the knowledge and skillsets needed to excel at his job daily. He is also loyal, friendly and a great all-around employee.

Charlie Singh, Divisional Manager at Joseph Ash Walsall, said: “Ranjit is well respected by his colleagues and always has time to chat with anyone around the site. At a recent Walsall charity event, we were thrilled to give him a gift and a celebratory round of applause to reward his quarter century’s hard work and loyalty to Joseph Ash and fellow team members.”

Congratulations Ranjit!

Next page

Welcome to our April 2023 newsletter.

Our latest newsletter is live! Published today.

This month, we’re celebrating the Lily Mae Golf Day, the World Day for Safety and Health at Work, and a successful Easter food bank drive.

We’re also discussing the top five benefits of duplex coatings; we meet a new Widnes plant team member (Paul Williams) and shine a light on our Joseph Ash Bridgend plant.

Finally, there’s a reminder for the GAGA Awards entry deadline and a reminder about our plant Bank Holiday arrangements. Enjoy!

To read a copy click here.

To receive a copy of the newsletter in your inbox each month please subscribe.

Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

Next pageFriday 28 April is World Day for Safety and Health at Work. It was set up by the International Labour Organisation (ILO) in 2003. The national initiative encourages and supports the need for organisations, labour unions, employers, and governments to create safe and healthy work environments. The goal: reduce accidents, illness and death for all visitors and employees to workplaces.

As a Company that prioritises health and safety at work, we proudly promote this day.

At Joseph Ash, our commitment to ensuring our plants are safe places to work and visit is 100%. Health and safety in any workplace are essential, but they’re critical in an industrial galvanizing plant.

Galvanizing plants can pose considerable risks to workers if proper safety measures are not in place. This is due to heavy machinery, hazardous materials, chemicals, fumes, and baths of molten zinc at temperatures of 450°C.

By implementing health and safety policies, procedures, and systems into our culture, ensuring all directors, managers, and supervisors hold formal health and safety qualifications, and introducing an occupational health scheme to protect and maintain a healthy workforce, we have an industry-leading safety record.

We also hold OHSAS certification for exceptional health and safety standards at all plants and head office. And we’ve been awarded the RoSPA Gold Award for six consecutive years.

Find out more about the World Day for Safety and Health at Work.

See our Health and Safety Statement and our Epidemic Health and Safety Policy.

______________

About the ILO

The ILO is a United Nations agency for the world of work. Since 1919 it has brought together “governments, employers and workers of 187 Member States , to set labour standards, develop policies and devise programmes promoting decent work for all women and men.”

Next page

This year we’re being spoilt for May Bank Holidays!

Not two, but three Bank Holidays on 1, 8 and 29, with the extra one for the King’s Coronation weekend.

We hope you have some great activities planned. (Perhaps some vigorous flag waving if you’re a Royalist!)

To help you plan your projects for galvanizing ahead of time, please note all our plants will be closed on these days.

Enjoy!

Joseph Ash Bridgend is one of our nine plants spread across the UK and the only one in Wales. We’re sharing some details about our services and facilities here, and the hardworking team members who make it all possible.

Joseph Ash Bridgend location

Joseph Ash Bridgend is situated on the Bridgend Industrial Estate in Mid Glamorgan and services clients from various areas, including Gwent, Herefordshire, Powys, Carmarthenshire, Pembrokeshire, Avon, Gloucestershire, Wiltshire, and Somerset.

The Bridgend team wants to make customers’ lives as simple as possible, so they provide collections and deliveries all throughout Wales. They also operate a milk run service to West Wales, Bristol, the M4 corridor and Herefordshire on a daily basis.

Galvanizing at Joseph Ash Bridgend

The team at Joseph Ash Bridgend galvanize all types of steel. In particular: gates, railings, and fencing; as well as specialised, delicate items requiring intricate care and attention such as sculptures.

In addition to hot dip galvanizing, Bridgend offers shot blasting through an external subcontractor. Through our network of plants, the plant also provides powder coating, duplex coating, and spin galvanizing.

Bridgend offers a collection and delivery service, full technical support, on-site storage facilities, and passivation post-hot dip galvanizing.

Bath size

The bath dipping size at Joseph Ash Bridgend is 4.5m x 1.35m x 2.1m, and the team can dip up to four tonnes at any one time. Fabrications larger than this can be transported to another Joseph Ash plant, using Bridgend’s fleet of trucks. The Bridgend plant offers a run twice a week to maintain their promise of quick turnaround times.

Flexibility

Bridgend understands that customers often have strict deadlines to meet. To assist them, they have extended opening hours for drop-offs and collections. They also offer quick turnaround times (overnight and within 24 hours) by prior arrangement.

Quality and compliance

Joseph Ash Bridgend commits to providing high-quality services and adhering to occupational health and safety, quality, and environmental management standards. The plant hold certifications such as BS EN ISO 1461, ISO 45001:2018, NQA ISO 9001:2015, and ISO 14001.

The Bridgend team are happy to supply Certificates of Conformity for each job when required.

Joseph Ash Bridgend team

The plant employs a team of knowledgeable and enthusiastic individuals, including shop floor operations, transport and truck drivers, health and safety experts, and an admin team.

Joseph Ash Bridgend is always ready to help and answer any questions about galvanizing, shot blasting, or powder coating. Contact Joseph Ash Bridgend today to learn more about their services and how they can assist you.

Next page