A one stop shop for steel protection

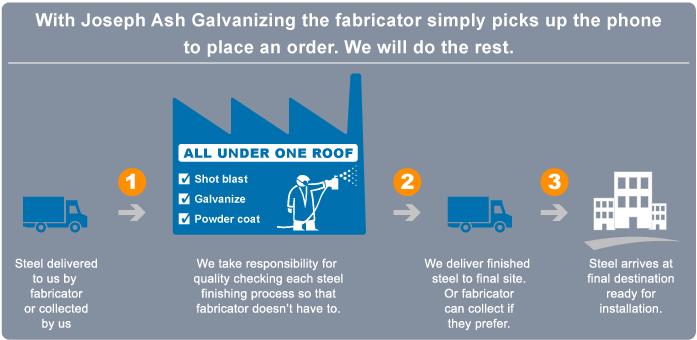

Joseph Ash Medway is a one stop shop for steel fabricators and end clients looking to protect their steel against corrosion. But what exactly does this mean, and what are the benefits of a one stop shop steel protection provider?

What is a one stop shop?

A one stop shop is simply another way of saying something is under one roof. The place is your “one stop” for everything you need. It’s a term most commonly used in retail, but it can also apply for service providers too.

In the steel protection industry, a one stop shop service provider is one that can cover all stages of the steel protection process. This includes any pre- and post-treatment, as well as your chosen coating methods.

What’s included?

Joseph Ash Medway offers shot blasting, hot dip galvanizing, and powder coating. These can be broken down as follows:

Shot blasting

Before any type of metal is galvanized, it needs to be cleaned of rust and uneven particles. One of the most effective ways to do this is with shot blasting.

This process strips off the steel of any existing rust or excess layers and prepares it for coating. In doing so, it enhances the quality of the subsequent galvanizing process by allowing the zinc to properly coat the steel.

It’s important that steel is galvanized shortly after shot blasting to avoid corrosion.

Hot dip galvanizing

Galvanizing provides superior corrosion protection for steel. In regular circumstances, it protects metal from rusting for multiple decades.

There are many benefits to hot dip galvanizing steel. The enhanced corrosion protection means you save money and time maintaining or re-fabricating the steel, and you can be assured that the steel will remain safe to use.

The process is also sustainable and fits into a circular economy.

Powder coating

Powder coating is an alternative to liquid paint that lasts longer, dries quicker, and is more environmentally friendly. Aluminium can also be powder coated.

Joseph Ash Medway is an approved AkzoNobel paint applicator for galvanized steel, giving you access to their high quality range of paints and colours. We’re also skilled in using powder coatings from many other suppliers too.

Benefits of a one stop shop service

Peace of mind – consistency throughout the whole process

Save the stress of arranging for timeslots and deliveries between multiple companies. By choosing one company for all of your steel coating requirements, you can be sure to receive the same level of quality and service throughout the whole process. You also only need to make one enquiry.

Turnaround times

We understand quick turnaround times are paramount for ensuring your projects are completed and returned to you promptly, without compromising on quality.

Our Medway site is proud to offer a standard turnaround of 48-72 hours on hot dip galvanizing and powder coating, with a premium 24 hour service available on agreed orders.

We’ll take care of the collection and delivery process across the South East of England, making the process as seamless as possible.

Environmentally friendly

Reduced CO² emissions associated with transport between multiple services providers can be achieved when everything is done in one place.

Additionally, galvanizing and powder coating are both environmentally friendly processes. Hot dip galvanizing fits into a circular economy, and at Joseph Ash, we have modernised our plants to capture and minimise waste emissions. Powder coating is also more sustainable than paint because there is less material waste involved. Most importantly, the process reduces the speed of corrosion, meaning there is less waste involved with steel refabrication.

One stop shop at Joseph Ash Medway

Joseph Ash Medway has been granted approved applicator status by AkzoNobel for their Interpon range of paints. We are also among only a handful of companies to be an approved AkzoNobel paint applicator, and are the only one to be based in the South East, in Sittingbourne, Kent.

- Collection and delivery service around London and the South East of England

- Save the time and hassle of multiple service providers, with everything under one roof

- Fast turnaround times – a 24-hour premium service available on agreed orders

- AkzoNobel approved applicator for powder coating

- A wide range of powder coating colours and finishes