Is galvanized steel weather resistant?

Many industries rely on their steel fabrications being kept outside. From structural steel buildings to farm gates and transmission towers, steel is prone to corrosion in moist environments. Fortunately, hot dip galvanizing serves as the perfect coating method for steel that is exposed to the elements.

What happens when galvanized steel gets wet?

Normally, when steel gets wet – whether from the rain or moisture in the air – it corrodes very quickly. When metals collect moisture, an electrochemical reaction causes the steel to corrode. The corrosion process is often accelerated by dissolved salts or impurities in the water.

Rust is just one type of corrosion but it’s one of the most prevalent types to affect steel. It occurs when oxygen reacts with metal atoms, forming metal oxides. Both oxygen and moisture are required for steel to rust. However, it’s very unlikely your steel will be kept away from oxygen if it’s exposed to moisture. Therefore, it’s important to slow down the corrosion process as much as possible.

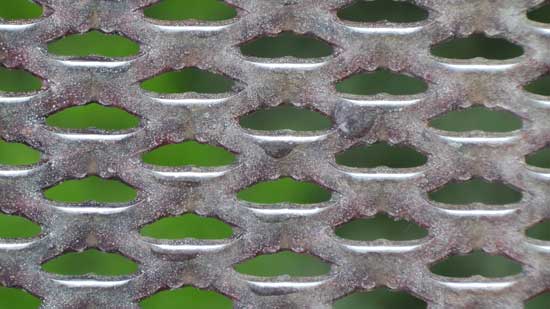

The galvanizing process involves dipping steel into a bath of molten zinc, causing the zinc particles to metallurgically bond to the steel. This bond creates a much more durable finish that surface-level coatings such as paint, meaning galvanizing is effective for protecting steel against atmospheric attack, such as heavy rain.

Is galvanized steel good for outdoor use?

Galvanized steel is good to use outdoors thanks to its corrosion-resistant properties. Structural steel, transmission poles, and agricultural equipment are all types of steel that are likely to be affected by weather conditions, among many other types of steel fabrications.

If you’re in the construction, agricultural, transport or energy sectors, galvanizing steel that is used outside means you save time and money on maintenance and replacements.

Outdoor paint for steel

Hot dip galvanizing is a reliable coating method for protecting steel against weather damage. However, you may be looking to add an extra layer over your steel such as paint.

Paint is often used to give colour to steel and add an extra layer of protection, but it can chip away easily, compromising the underlying steel. Even when using waterproof paint, it is advised that you recoat it every 5-10 years. But what if there was an alternative to paint that doesn’t need retouching so frequently?

Fortunately, there is. Powder coating is a method of coating steel that adds colour without compromising on durability.

Powder coating is the best alternative to paint. Unlike paint, which chips easily and does not protect against corrosion, powder coating is applied electrostatically to the steel. This application technique means that the layer of powder coating protects the underlying steel against corrosion. Powder coating used in synergy with hot dip galvanizing is known as a duplex coating.

Joseph Ash Galvanizing for durable steel

With nine UK sites, we’re never too far away to protect your steel.

- We’ll collect and deliver your steel to our site ✔️

- Comprehensive technical support, guidance and assistance at every stage ✔️

- Hot dip galvanized to BS EN ISO 1461 standards ✔️

- Part of a circular economy ✔️